joeblowma

Members-

Posts

31 -

Joined

-

Last visited

-

Days Won

1

joeblowma last won the day on June 25 2019

joeblowma had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

joeblowma's Achievements

Member (2/3)

6

Reputation

-

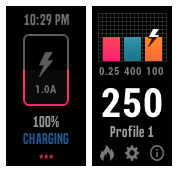

Does it have SP38 early release firmware on it? As far as I know they haven't pushed this into the main recommended package yet, that one comes with firmware SP35. https://forum.evolvapor.com/topic/66731-early-firmware-and-escribe-suite/?do=findComment&comment=929633 This cured about 98% of the (false) throttling issues for me. Still does it from time to time, but very rare now. Interestingly, I can still induce throttling in wattage profiles by manually setting the resistance to double what it actually is.

-

my Paranormal DNA 250C stuffed, many problems

joeblowma replied to greg q's topic in General Discussion

@Lanzarotechris it's supposed to adjust the power to remain at a set temp to protect from dry hits. The problem is, when these mods flash "temp protected" on the screen it's doing no such thing - it's just cutting power to the coil entirely, more often than not before it's even heated up (aka: spurious/random/not appropriately.) Other mods usually show 'temp protect' on screen or similar whenever it's throttling the wattage and a different error if there was a fault that caused it to stop firing entirely, for whatever reason Evolv decided to be different. If you read back in the thread I was able to always get a 'temp protected' error if I manually set the coil resistance a bunch higher than it actually was. Again though, the problem is (mostly) solved in the early firmware pack on the thread I linked to. -

my Paranormal DNA 250C stuffed, many problems

joeblowma replied to greg q's topic in General Discussion

SP38 firmware update fixed most of my Temp Protect cutoffs ( Fixed spurious Temperature Protected errors that could crop up in certain high-CPU themes with Replay off. ), still happens very rarely for me but not nearly as bad as it used to be no matter what theme. As to the operating system, I think the theme engine was a little more ambitious than the microcontroller was meant for - plus as far as I know 75C and 250C design was finalized back in 2016 and with PMTA looming (they are a US manufacturer after all) no idea if we'll ever get to see anything better. In my opinion they still did very well with what they have, though I've always wished for more from my computers too! -

It's in no way as involved as a laptop screen, those things need to be built for rigidity (and I've seen more than one fail because they weren't or worse the hinges were badly thought out.) Worst case there is some double sided tape holding the screen to the frame but IIRC it's just some tape strips down the two side and once you lift those and the screen/glass itself you might even have access to the connector and not even need to get the supporting frame out. I'd have to open it up again myself to be 100% certain as when I've gone in it wasn't to get access to the board at all, but every build I've seen around these screens has been more or less "tape it to a frame" or "put something behind it to hold it into a frame" and in paranormal 250c's case it's definitely resting on top of the frame.

-

Not much further, the screen is sitting in a tray and you'd probably have to figure out how to get that tray out to get at the connector.

-

For what it's worth I think if there are any design issues we can blame the US FDA for that - evolv had to finalize and sell the final design before the deeming deadline barring further changes without PMTA approval (which is unlikely except with more closed systems) which I'm guessing was met by copious crunch time... it's also why the US firmware doesn't have some features found in the INT firmware. I can say the betas did correct most of my issues with SS though, still get the occasional 'temp protect' where it doesn't belong and any time I've run into pulsing TC it's been down to my build (ie: coil resting on the block where the grub is rather than just held by the grub, inconsistent coil spacing, things of that nature).

-

I got that message in watts mode when the saved cold resistance was a fair bit higher than the actual resistance of the coil (for example a 0.32 ohm coil will give throttling message instantly if the saved value in the watt mode profile I have is 0.524 or higher), usually after rejecting a new coil message.

-

I think he added a bit of info on that beta test firmware post at some point after, noticed late last night... I'm a bit dubious about the 'high cpu theme', as I pretty much castrated the gauges theme to do nothing on the main screen and it was still an issue. Either way, 2398 puffs later I've had it occur 3 times, 729/924/981. Yes, I checked and wrote it down each time it happened because it's happening so rarely now. So... much better than it was.

-

Well, to update... going by the puff counter it took 729 puffs before I hit a "throttling" message, at 886 now with no recurrence. Keep in mind I had gone over all the soldering as a first attempt to find a solution, with this version of the theme (I customized gauges to have some different default fields and to re-link the info icon on the main screen to the graph screen) I'm using now I was getting as many as 4 in 10 puffs interrupted with rare longer gap of 20-30 puffs with no issue. Because of that 1 puff I can't say it's 100% fixed, but for me at least it's far far better.

-

So far so good! I reverted to a version of the theme that was giving me problems more often than not, disabled replay recording in the TC profile (which was my working workaround to avoid the problem as much as possible) and have yet to run into a halted fire/temp protect event in the last couple hours. At least replay works. They may care slowly, but they do care.

-

Yup, I saw - plus you changed the temp output location to the big number display which doesn't work so great with wattage modes. I was pulling conditions off those one or two at a time, hoping it was just one thing that made a notable difference but none of them reached the effectiveness of yours. Have you tried the workaround I've been using... enable 'can replay' in the profile, but just don't use replay to save at all? I'm not sure the changes are just to the theme when that is enabled, it could be the entire TC method is switched over to something else in the process. As these boards alone go for around $95CAD, and all of my $65CAD or less TC capable full mods can get through a TC puff (though to be fair a few of them needed ArcticFox to do so, OEM didn't cut it)... I too am disappointed. R.I.P. "At least Replay worked."

-

This one is an improvement (though it leaves some modes a little broken), inline with some of the other themes I've tried. It took a good while before I started getting them with this one, but they did come back just not at the frequency it was occurring - about inline with other themes I've tried. I tried whittling through the differences between yours and the regular one and wasn't successful at pinpointing anything specific - just removing one condition (the middle number on the fire screen has conditions for both 'replay' and 'fire and replay' that do the same, I removed 'fire and replay') was a marginal improvement anything more was back where I started.

-

I gave mine a factory reset, uploaded a save of my settings, then uploaded the theme (the version I edited to allow temp change while replay is enabled in the profile) with the lock screen battery icon replaced with the default tiny one (75c:71.6%/60% 250c:71.6/50.8 off/on board) and as expected the problem went away for the first while but came back. I even let it sit for a couple hours just to make sure it wasn't a "works great until it gets warmed up" situation which would point to a component issue, but coming back to it and it picked up where I left off with the bad puffs. Turned back on replay option (but still have never bothered to lock a puff) in the profile and... no more problems. Yay for random things working!

-

First, take out your batteries. Take out 2 phillips screws by battery door hinge at the bottom front of the mod (marked as 1), remove the battery door. Under the battery door is 1 screw, then 2 more between the batteries (marked as 2, though one of them is under the battery door). Once these 3 screws are out with some gentle pressure the bottom of the mod just pops off directly down. Take out the 3 screws around the 510 connector, and the 2 screws on either side of the frame on the opposite end of the two for the battery door (marked as 3). Once the bottom is off and those other 5 screws are out, you can grab that front panel part down below the usb port (marked as 4) and pop it forward and up. This gives you access to the buttons and piece I was taking photos of previously.

-

multiple ui Gauges - Major update 2.0.0

joeblowma commented on SirTimmyTimbit's file in DNA 75 Color, 100 Color, 250 Color

No worries! It was just something I stumbled on at the beginning (have since learned there actually is a way to download the puff recordings through Device Monitor, which was equally unhelpful) of my attempt to get as close to the bottom of interrupted TC puffs as I could, it was quite easy to tweak the box size but I figured I should mention it.- 150 comments

-

- 1

-

-

- replay

- minimalstic

- (and 10 more)