-

Posts

227 -

Joined

-

Last visited

-

Days Won

11

Podunk Steam last won the day on October 6 2024

Podunk Steam had the most liked content!

Personal Information

-

Full Name

Wylie Wiggins

-

Location

Podunk Idaho

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Podunk Steam's Achievements

Senior Member (3/3)

40

Reputation

-

A Linux phone would be a thought, but I doubt I'll personally go any further than the thought.

-

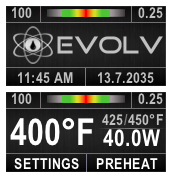

Before I go too far, this is from a Linux perspective, LMDE6 running SP57 on this system in conjunction with a DNA 75C. So far "day2ish, a couple of hours of total tinkering", I've found this theme to be slightly counterintuitive with the Xs and Checks of the indication boxes but easily comprehended and adapted to. I've managed to make a few adjustments for the old aging four-eyes, with adjustment texts switched to red text and adjustment highlights in a brighter shade of green than the near matching blue to the black background. My only real shortcoming with this very well-prepared and configured landscape theme is my inability to add decimal incremental adjustments to the profile screen itself in the theme designer. Could be a Linux glitch, I really haven't dabbled enough to know all the ins and outs. In the atomizer screen, I have managed to add the decimal integers, so the functionality is in place for my oddball MTL wires being used for direct lung vaping. Outside those few points, this theme is by far one of the more appealing themes I've used, without question, and I've been through more than just a few. Excellent use of space allotted with bold texts, wide scope of functionality and visually appealing.

- 2 comments

-

- 1

-

-

- dovpo

- steamcrave

-

(and 3 more)

Tagged with:

-

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

Any suggestions, I mean besides some new 10 amp Sanyos? https://ibb.co/LN8Vt0j -

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

Just checking in with a minor scaling issue in the monitor display section of the latest internation Linux release. Kind of a blast from the past as I've looked around a bit and didn't find an option for resolution, pun intended. I'm using LMDE6 on this rig, the monitor is completely functional, just the scaling is off a little, likely because I use fractional scaling at 150%, old guys eyes. No biggy really, just a heads-up. Picture link https://ibb.co/0VDPZwQ -

Your picture helped me out in a huge way, Bill! My hyperion was sitting for months until moments ago. A pocket knife blade between the button's house and the body of the mod with a little friendly persuasion in a few areas to break loose the adhesive and the actuator plate released. After trimming the broken plastic "spring" parts away (the two small legs from both sides), I used about half a drop of contact adhesive to glue the plastic actuator that broke away to the interior of the switch's plate and we're back in business. Thank you sir!

-

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

I thought I'd take another run at an MX Linux install being it's Debian based with SP50us, it didn't fly and SP50int didn't either. I checked all the prerequisites which were already installed, gave the .run file permission through properties and Gdebi-gtk said (Could not open 'SetupEscribe2_SP50_US.run') same with SP50_INT Said something about the file could be corrupted or I don't have permission... I do have administrative permission and was signed in. As many years as I've used Linux (since Ubuntu 9.1) I should understand the Terminal prompts better than I do but I don't. Got script? I'm not the VM type and already have Escribe on this notebook in the Linux Mint 20.2 drive so it's no big deal, just doing a little testing with the possibility of convenience in not rebooting while I'm in MX Linux drive. Edit: I went looking for terminal prompts and finally got Escribe installed on MX Linux " MX-19.4_x64 patito feo" the information I found was on YouTube, try at your own risk! -

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

Thank you for the reply! LMDE 5 is different as it's Linux Mint "Debian Edition" where most or all Linux Mint distros are Ubuntu based. I've been using Escribe on Linux Mint Ubuntu versions for quite a while. Ubuntu is getting a bit bloated for older slower system and Debian is generally very stable and fairly light weight is my reason for the interest. I have read of the new Debian installer thanks to @James again which I may have to make a run at once my RAM and SSD arrive. Yep me buying DDR2 in 2023, go figure! LOL! -

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

Checking in to see if anyone has installed on Linux Mint LMDE 5 yet? I haven't even test driven it yet. My old desk top is now my entertainment center server temporarily and Evolv Escribe might be a nice option. Sep. 2008 built HP Pavilion Dual Core Pentium E2200 boasting a whole 3GB DDR2 RAM, same old 500GB HHD. Yes, if it were butterfly inter-netting they'd all get away! -

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

The X470 may be worth researching as there have been issues with both Microsoft and Linux related USB ports acting janky. This is one of numerous reports. -

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

I won't be able to follow up any time soon but did you start with the simple stuff like making sure you're using a good data cable? Check the USB with another data device? It's been quite a while since I have had to designate USBs with any Linux distro, that's going back to the 9.x Ubuntu distros thinking about it. -

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

Looking sharp! My Mint theme was adopted with this update. -

Hyperion DNA 100c High Contrast Theme

Podunk Steam commented on Gatok's file in DNA 75 Color, 100 Color, 250 Color

I've had no issues with this theme. I didn't go through every wire profile but 316 and NI worked fine for me. The puff counter is on the Replay display. There is a slight counterintuitive nature being settings are changed while highlighted but that's no real issue. It works well. https://i.ibb.co/1d5Tzwp/20210908-231354.jpg Jealousy in the air? Amimosity maybe? -

Hyperion DNA 100c High Contrast Theme

Podunk Steam reviewed Gatok's file in DNA 75 Color, 100 Color, 250 Color

-

Linux EScribe Suite Beta Thread

Podunk Steam replied to James's topic in EScribe, Software and Firmware

I've just updated a Linux laptop with 20.1 Mint Cinnamon and installed Escribe. I've done previous installs of Escribe that have taken on my computers theme, I'm a dark theme type, this time my computers theme was not adopted by Escribe. Am I asking for trouble trying to incorporate my computers theme? -

No sweat! The only reason I bought this mod was it looked to have the potential for this swap if the original circuit didn't pan out for me. The only other part that's a little tricky is widening the bed for the display. It seems to be a pretty soft ABS plastic and can be carved with a knife easily. I did just that, took my time at it with a knife, that was the longest part of the process.