-

Posts

2,610 -

Joined

-

Last visited

-

Days Won

135

Content Type

Profiles

Forums

Downloads

Posts posted by retird

-

-

Could it include the EScribe Settings (.ecig) file for the Opus enclosure?

-

If it were the board wouldn't it do it with any version of firmware?

-

So is it that the device gets hot at the battery area? Previous Hcigar VT75's had a cathode screw that when not tight would cause the case and battery to heat. The nano doesn't have the cathode screw but some report the device heating of the case and battery on the nano also. Some say cleaning the battery cap and threads of the device where the cap screws into helps with unwanted heating at the battery area. Some atty's get hot with use. Don't know if this is what you are seeing but just passing along some info....

Good luck... -

@dwcraig1 is correct. The DNA 20D small screen's ribbon is soldered to the board. The only way I think you could add a ribbon extension is to solder the extra ribbon onto the DNA20 ribbon and then solder it to the DNA20D board. I guess you could find a connector set to solder to the ribbons and connect the extension that way but will still have to solder the extension to the board. There is no Zif connector on the board.

-

You should see that the Li-Po will charge to 4.20 volts each cell with pack voltage at 12.60 volts when the device is set to maximum puffs. Continue to let it charge and see what the full charge looks like... The lightning bolt in the battery bar of the device should go away when the battery pack is fully charged.

The 11.1 Volt spec is 3.7 volts per cell nominal. -

Didn't recall there being a thread for this device so here we go.....

Been evaluating this new device for about two weeks now. They did an excellent job IMO programing and setting up the mod settings. I ran it in power mode with Kanthal for a week with typical results then switched to TP (Temperature Protection) mode. I use the notch coil (SS316L) in a RTA and I like to use it when testing and evaluation a device as it is not a wrapped coil. It is very stable and consistent and it is my go to "reference coil type" for all testing and eval's of Temperature Protection mode.

Been tweaking my settings and vaping. SS is very smooth on this device also and since the notch coil heats quickly I can adjust pre-heat wattage, punch, and duration accordingly. I try to find the "sweet spot of pre-heat" whereby it uses just enough pre-heat settings to get the job done without using excessive pre-heat settings (doesn't punch too hard). I also try to set the wattage at the "sweet spot" where the wattage is enough to do the job but not excessive (vapor control). The temperature is set to achieve the best flavor production.

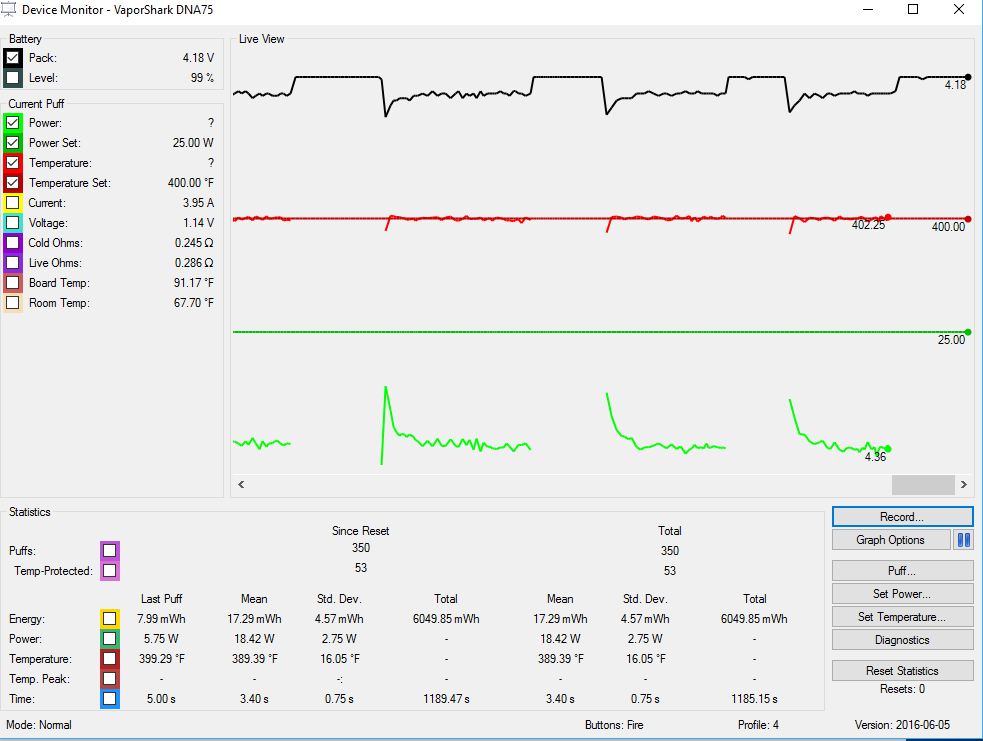

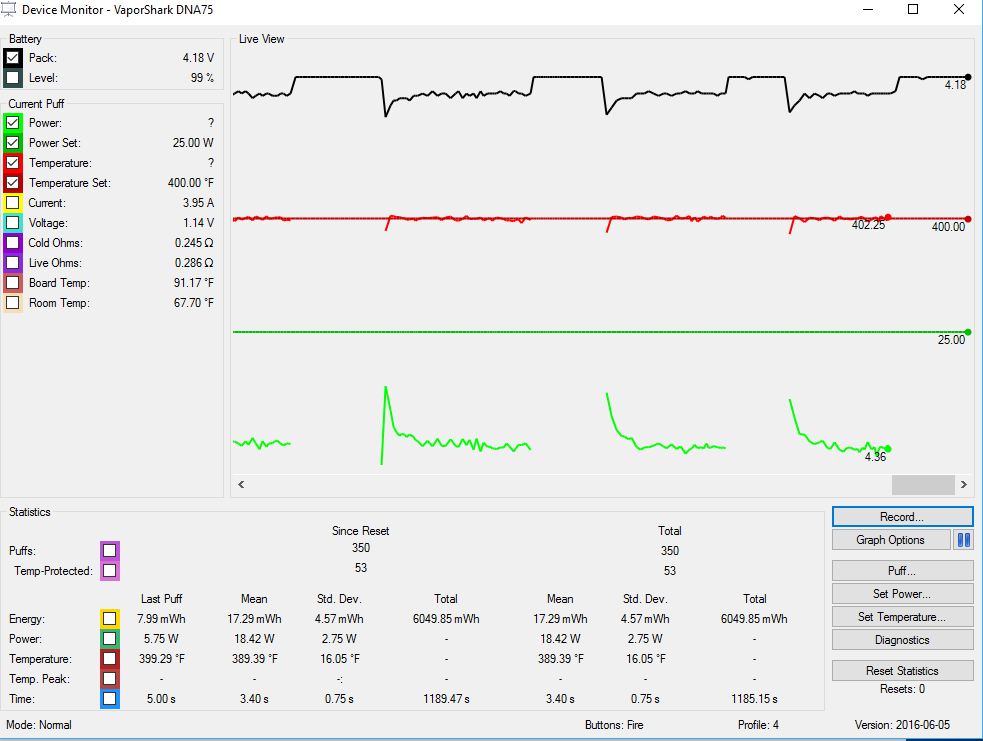

Think it is tweaked pretty close to acceptable. Captured another screen of the Switchbox from EScribe. Fired the device 6 times while not vaping so the air flow wouldn't vary. The screen here shows the end of firing number 3 and the next three firings after that. The DNA75 is monitoring the temperature and adjusting as designed per the set temperature. As you can see it is a very smooth and consistent even with multiple firings. As you see when the temp goes above the set temp it is regulated down and when it is below the set temp it regulates up. That's as expected and designed. You can see in the info at the bottom where the "Last Puff" sequence temperature is 399.29 F. The Temperature setting is 400.00 F.

I could go on with more info but the post is getting too long I think.

Here is the screenshot:

Anybody else out there rocking the Switchbox? -

You not getting any error messages?

With it set to 120 watts with a .18 ohm Kanthal coil it should fire.

So in EScribe while firing it only reaches 80 watts while firing? What will it show while firing and not vaping (no airflow)?

I've got to sign off for 5 or 6 hours so maybe someone else can chime in...

Are batteries charged and balanced?

What about battery sag?

Maybe a lot of mass in the coil requiring more time to heat up but some reviewers say no ramp up time. -

In EScribe what is the Kanthal Power Limit set at in the Mod Tab?

-

I use notch coils and never lock the ohms. On a new coil what cold ohm reading do you get? What is your notch coil's manufacturer's stated ohm's reading? What ohm's reading did you lock it at? The notch coil uses no resistance wire for connection to atty deck. Those 2 wires connect to the notch coil that is SS316l. If your ohms are fluctuating I suspect poor connection at the deck or poor connection between the atty and device 510 connector. Does it wick well?

-

-

Enjoy and folks around here try to help should you have further questions...

-

fibercarbon said:

The latest fw version for the DNA75 is 2016-06-05. Open Device Monitor with device connected and look in the bottom right corner for the fw version... If your device is new I suspect it has the latest fw already installed. -

Good starting place to download....scroll down in this link..

https://www.evolvapor.com/products/dna75 -

Or, if you use different atty's with different wattage, temp settings, etc for only watts or 316l wires you could set up profiles (up to 8) for each wattage, temp setting, etc. of each wire.

-

6-5-2016 is the latest firmware version for the DNA75. Check the lower right hand corner of Device Monitor and the Switchbox should show that version.

Vapor Shark did an excellent job programming the Switchbox with the production utility. -

Lots of info here on the 250 board...

https://downloads.evolvapor.com/dna250.pdf -

Vaperkarloz said:

Mine (wood paint finosh )has unusal pike un temp before stabilizes temp 6-18c spike is short lastimebut has happened on all atty ive tried, apatently the spike in tc is not normal.....

Lots of things can cause what you call spikes. Posting screenshots of Device Monitor data can help those of us who want to help you. Continuing to talk about it without letting us see screenshot data will probably not bring about the answers you seek. -

Wayneo said:

Has anyone managed to retest with this latest SP5 to see if this is working again? I know mine is somwhere around here, I'll just have to hunt it down.

If I am not mistaken they are still working on that one.... Still ? here..... -

So by saying "randomly doing a power reset" do you mean the device resets and the Evolv DNA75 startup screen comes on again like the board is loosing all power from the battery? Possible loose connections, poor grounding, issue with the wiring. Best guess from the limited info you say. A short video showing what you are seeing may be helpful.

-

If you didn't save the .ecig file from your device maybe somebody here has an .ecig file for you... Maybe contact your vendor....

-

Guess I'm one of the "morons" too....

-

Mgeli said:

Hi. After upgrading to 1.2 SP5, can't log in to my account and Escribe to obtain information about my mod.

Yep, same here and others say the same.... Evolv will get it fixed.... it may have to do with Evolv recently moving to a CDN for their downloads, since the traffic was getting kind of high. At least that's my guess....

A content delivery network (CDN) is a system of distributed servers (network) that deliver webpages and other Web content to a user based on the geographic locations of the user, the origin of the webpage and a content delivery server.

-

Evolv came with Temperature Protection as a means to vape in a safer manner. Temperature Protection allows vapers to adjust and control to safer limits thus reducing the amount and number of bad things that come with high temp, burning cotton and juice, and etc. As Evolv states in their data sheets:

Temperature Protection

The DNA 200 directly measures and limits the temperature of the heating coil during operation. By preventing the coil from becoming too hot regardless of fluid, wicking or airflow, a variety of undesirable situations can be prevented. For example, appropriate temperature settings will prevent the wicking material from charring, which compromises taste and introduces unintended chemicals into the vapor. Appropriate temperature settings will also reduce the breakdown of flavoring and base liquid components, which could impact taste or safety. -

Has the film of the organic compound (black part of the crystal screen) changed shape since you posted the picture 9 hours ago? Can you post a more close up picture and picture of your board?

.thumb.jpg.a21e2bc6a6a2439a8c97330238778481.thumb.jpg.f6954db18188e59ab08f3ac385c64286.jpg)

Therion DNA75 SS316L Issues

in EScribe, Software and Firmware

Posted

Any hot spots in your build. A hot spot can cause a quick temp protect message when coil actually hasn't heated to temp. I suspect coil build or connections as opposed to having a lemon from what you say...