-

Posts

604 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Downloads

Posts posted by blueridgedog

-

-

At times, if it has failed during an update and all the computers sees is the recovery device, you should remove all other USB devices and do a clean power on with the DNA200 connected fro cold boot.

-

Glad you got it sorted. The current release of VirtualBox works with W10, all others do not (as it relates to USB).

-

It is a common issue, especially with lower TCR wires, to decline to fire in TC mode. As VB pointed out above, that simply means that the chip failed to see the 150 degree change and assumed it was non-TC wire. 95% of the time this is a loose leg or a hot spot.

-

Johan said:

[QUOTE=blueridgedog]I like the SSV wire. Yes it is an alloy, but with the right profile, it is a great vape, easy to work with and durable. If I could find annealed Ti that I could bend and have it stay that way, I might switch, but having used pure Ti and having four Ti ignitions (the Ti burns) in my atomizers, I have been reluctant to go back to it.

Could you describe the circumstances of these ignitions? That is a scenario that I would like to avoid replicating. Thanks[/QUOTE]

Taking non-annealed ti and annealing it manually so it is not springy. The end result may be uneven, and a hot spot may form when vaping...pop. -

I like the SSV wire. Yes it is an alloy, but with the right profile, it is a great vape, easy to work with and durable. If I could find annealed Ti that I could bend and have it stay that way, I might switch, but having used pure Ti and having four Ti ignitions (the Ti burns) in my atomizers, I have been reluctant to go back to it.

-

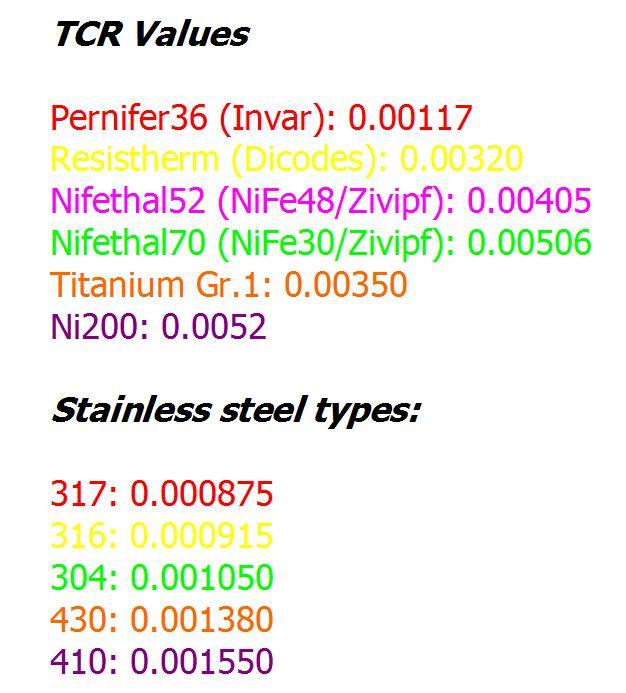

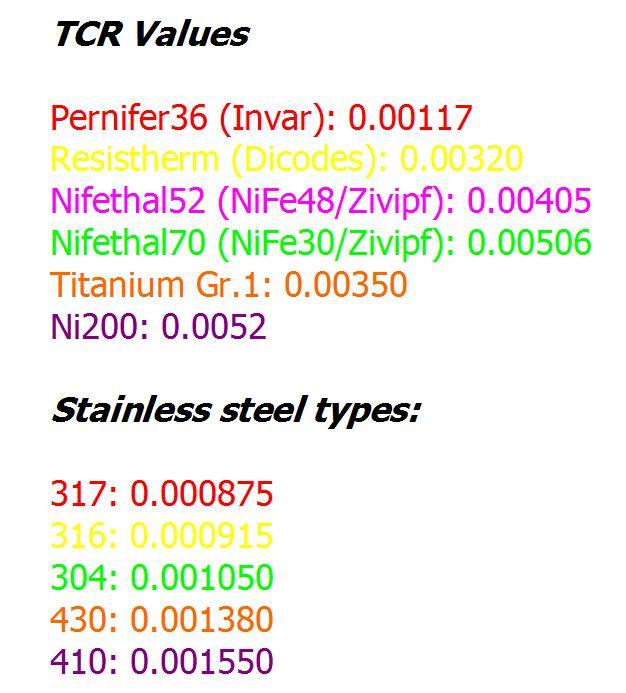

I have seen recommendations for a minimum of .5 resistance for SS. The lower the TCR, the higher base resistance that is required as you are dealing with a ratio. Small Resistance*Small TCR = small variation, Large Resistance*Small TCR = better variation when fired. If you multiply the two you get a baseline target:

Wire min Res TCR X Ni200 0.05 0.006200 0.000310 Tungsten 0.07 0.004500 0.000315 Ti01 0.1 0.003500 0.000350 NiFe30 0.1 0.003200 0.000320 SS430 0.25 0.001380 0.000345 SS304 0.5 0.001050 0.000525 SS316 0.5 0.000920 0.000460 SS317 0.5 0.000880 0.000440

-

Effie said:

Hi, I seem to be having the same problem with charging my Opus last night it just didn't charge, Update ver 8/21 and performed a USB Recovery charging. As of now Pack is at 10.79v cell1 3.60v cell2 3.59v cell3 3.60v the recovery hasn't fixed the charging problem. Is it something I need to ship back to Opus or a work around that I can do. your help is greatly appreciated.

Some of my DNA200 mods fail to charge as well, but this is due to some USB cables not being inserted far enough. I have gotten accustomed to inserting it firmly, looking for the "click" then looking at the screen to be certain it is charging. -

Any timeline on the 1300 size? Sad it has a non-evolv 510 thread, but open to look at what you have. I have a number of them that need homes.

-

The warm atomizer issue is worth shinning a light on as it is the source of a lot of issues with TC vaping (not just the DNA200). If the coil is not at room temperature and you attach it to a TC device, and use the device's logic or user interface (New up, old down) to tell it that you have attached a new coil, then it will be impossible to get TC control on that atomizer. The TCR values at play are so very small that small variations in initial resistance (due to the coil being warm) or mod resistance (improperly entered mod resistance figure) will dramatically through off the TC calculation, typically in the "up" range, i.e. the board will give more wattage than needed.

As we on the "early adopters" forum try and help those out there use this technology, we need to keep in mind what it is actually doing. I get this a great deal with my wife...vaping, happy, pulls atomizer off to fill it, puts it on, tells the device it is a new coil because she is accustomed to blindly clicking "ok" when doing things on the computer, then gets bad vape. I have solved this by having a rule for folks that I help with the DNA200 "thou shall never put a recently used atomizer on the device". I keep six identical atomizers ready to go and she swaps to one of those if she wants a "refill". Do I follow this?

Can this be made easier for the user? I don't think so, but it could be that the DNA200 could have some logic that kicked in that observed sooner that the resting resistance was falling and that the base resistance being used is off. It has that, and that is why the room temp calibration is essential, but for now the window of time required for it to naturally correct the user input error is long enough to cause user experience issues. -

As a final suggestion, SS is an alloy and each can have slight variations from the standard formulation. Take ten samples of 316 from ten manufactures and you will get a variety of real world TCR values, depending on the exact composition of the wire. Ti and Ni are easier, in that they are generally in pure form and therefore easy to dial in.

-

Bobby said:

Hmmm, it's my impression that most of the factory coils and popular wires tend to be 316L and the 'succes stories' I see use this wire or these coils.

Do I understand you correctly that you are saying that true TC on wire that has a TCR in the 0.001 region is not possible, so the succes stories I read of SS316L are actually based on vaping this in VW mode with a temperature limit (like the first screenshot of Vapertron)?

I will see if I can get some SS410 to test if this will do true TC. In the meantime it would be great to see a screenshot of the device monitor with this wire.

I think there are success stories with 316/317 but there are also a lot of people vaping it in VW mode, and some probably do think they are in temp mode. The TCR of these is so low that you have to have a significant coil and a near perfect atomizer along with a base resistance figure in the escribe setup to get it right. The DNA200 is the only chip that will let actually see how it is scrambling to use it in TC mode. -

I have to pay very close attention to the registered resistance of a mod when using "lowish" TCR value wires. If I know the build is .12 and it starts reading .13, .14 or worse, then I have to stop, move on to another atomizer and open that one and see what the issue is. 99% of the time, I simply tighten the grub screws and it falls back in line. Other times I have to pull the deck and clean it.

-

316 and 317 have a pretty low tcr. Many of the success stories you hear are based on 410 and the other higher tcr value SS blends.

-

lewisss said:

Not sure where you got that from as I have not seen anything like that from evolv officially (unless you are from evolv maybe) I am talking as a self coil building dripper only vaper. And I have found that particularly with Ti and Ss there is a while to 'break in coils' So ythe perfect vape with a ss 317 coil with the steam engine tcr is attained at about 330 f initially but throughout the day the temp required to get the same vape increases gradually until it settles down around 400-420. So yes temp control is a must for me. And with regards to your assumption maybe if that were the case they would have marketed the dna200 as 'dry burn protection ' rather than temperature control...... Just my thoughts

This is from discussions with Evolv staff regarding the intended use of the temperature setting. From their design perspective, they see the temperature set point as a max that you want to hit, then you control your vape with wattage.

This has exposed two camps of folks, those that use temperature to get the vape they want and those that use temperature as a protection point and use wattage to get the vape they want.

I am in the second as I keep my DNA200 set at 200pre and 200fire and use temperature to set the vape quality. Vaping Bad I "think" is in the first camp, in that he sets a not-to-exceed point for his temperature and then gets the desired vape with wattage. -

You could try the Evolv RMA process.

-

There are no editing of posts here. Stainless, especially the 316 and 317 is challenging. What most folks are finding is essential:

Solid connection

Solid atomizer

Dialed in mod resistance

This gives the mod the best chance of seeing the small TRC range of the coil.-

1

1

-

-

There are many types of SS, some work for TC, some don't. Even under ideal circumstances SS may come out of TC mode as the TCR value is a narrow window easily overridden by variable resistance in the mod or atomizer. I don't think there is any change that can be made to make the board deal with it better, unless you want a TC mode lock.

To make your post better, can you list the type of SS you are using and the curve you are using for it? -

I understand a modal window, and when it is used vs not. I have 30 years in the same field though it is rare to code anymore as I have been the CEO for a decade. I think that the use of a modal approach to block state changes that would otherwise have to be coded with locks and a call layer is acceptable for a hardware company that is writing software. Ideally down the road they will outsource escribe to a software firm with an outcome along the lines of your (BobC) expectations. I too would rather see a mobile version, but as this is very new ground I am happy with the pace. I don't use or own windows gear so it is a challenge to make it work in my environment, but I don't object.

-

From about 20 days ago:

https://forum.evolvapor.com/topic/67310-topic/?do=findComment&comment=905796

Keep calm and have a vape folks. -

Success...OSX 10.11.03 and VirtualBox 5.0.14r105127 works.

-

Ok...this is microscopically newer than mine. I will try it with my 10.11.2 mac. I see you are trying a win10 host that may also make a difference.

-

My only concern with the blade fuse if the speed. I am not certain it will protect the device.

-

Brandon has implied the next release will be significant. No hurry as I am not in need of escrib regularly and have very little on my firmware wish list.

-

Can you post your version of VirtualBox and the version of the Guest addons? I see you are on 10.11.02 OSX correct?

Anyone ever look into custom cnc box for a diy mod?

in General Discussion

Posted

$60 per enclosure in volume. Lower with higher volume.