-

Posts

237 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Downloads

Posts posted by Jaquith

-

-

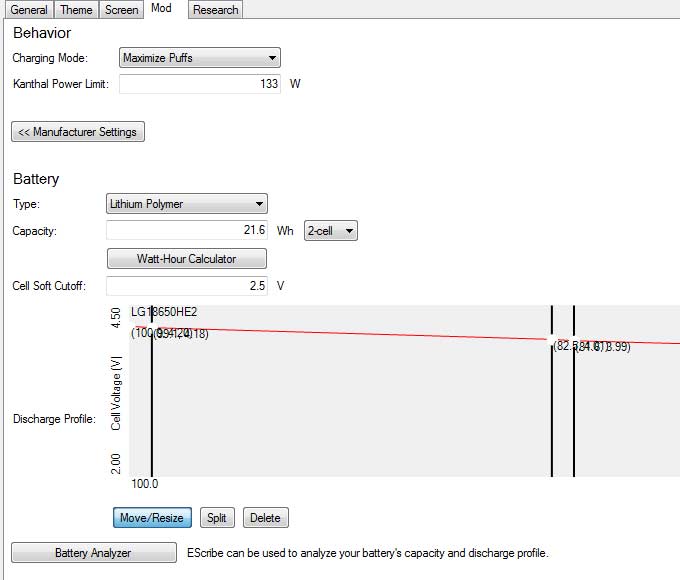

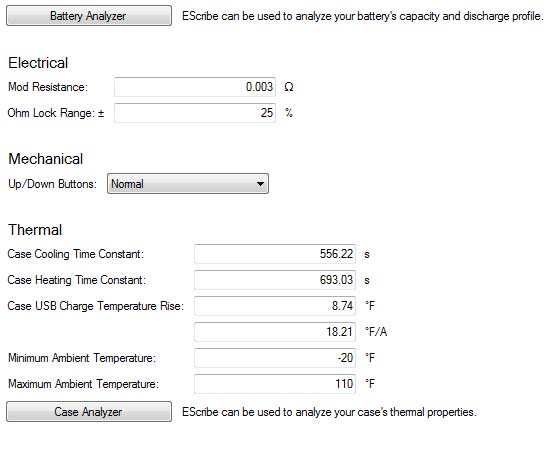

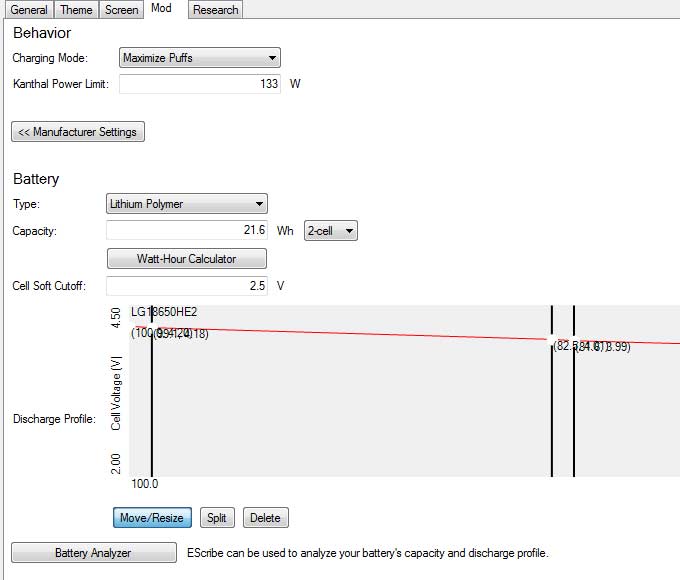

Okay, interesting 'stacked' suggests 'series' so 1st you need to make certain you have the latest firmware, next you need to properly wire you Balance charger, lastly that your Mod is in 133W and 2S mode.

1. Wiring the 4-Pin Balancer (my guess this is your problem); see https://s3.amazonaws.com/files.websitetoolbox.com/186396/2411946 from thread from https://forum.evolvapor.com/topic/66226-topic/

2. Latest Escribe - https://forum.evolvapor.com/topic/66731-topic/

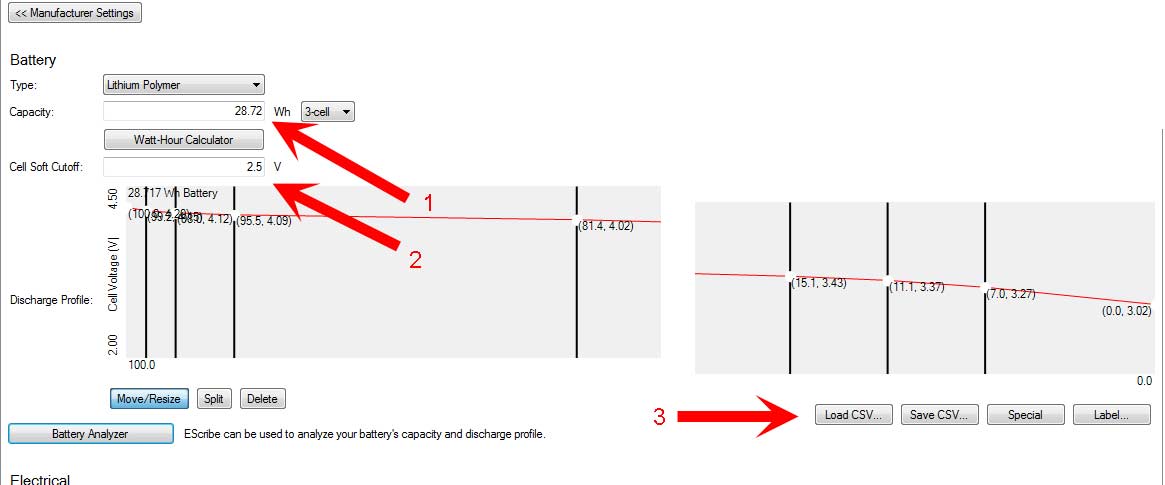

3. Settings; example from one of my Mods:

Load this 2S Battery Profile to get yourself started - http://www.filedropper.com/lghe22s18650

Good Luck!

-

jj6404 said:

Ah. So do you think I should continue to use the build I already made and eventually the "gunk" may burn off? Or should I just ditch it?

I'd just clean it, take the deck off the Atty and soak it, rinse and brush, repeat then dry burn on low. Making a Clapton is a pain. -

Oh trust me I completely understand what you're saying about the Kanthal. What works for me is unspooling about 10' (3 M) and wipe from one end and in one direction then respool. 70% should be fine, the alcohol helps disolve and clean the 'gunk.' Yep, I carefully dry burn my Titanium spaced coils, keep it 'dark orange' and clean with a soft brush (I use an old clean toothbrush). Done carefully it will perfectly clean the coiling and not form any TiO2 white deposits.

-

jj6404 said:

I just can't get over the flavor difference with SS vs titanium. I just built a Ti1/KA1 clapton dual coil and it just tastes...funny. I only asked about SS430 because it's popular on that Unkamen site that everybody talks about. Also (and this I don't understand) on the site it lists its 430 as "nickel-free". Doesn't all SS have nickel in it?? It wouldn't be SS430 anymore without I would think.

SS430 .. I listed the composition, it has less than 1% Nickel and has about 20% Chromium. As far as Titanium having a taste, absolutely not, it's a tasteless & odorless metal assuming you have cleaned Grade 1. Kanthal is especially on a Clapton is more than likely your culprit, I'd imagine your fingers had nice black streaks .. so I'd clean your coil .. soak in alcohol, clean with a brush, soak in water and then allow to dry.

BTW I clean all of my wire with 91% Isopropyl alcohol before wrapping the coils, clean as stated above, and then low wattage pulse (dark orange; 10W single / 20W dual). The problem is in the processing especially polished wire gets machine oil and metal dust embedded into the wire.

Here's a good link with the composition of various SS grades - http://www.stainlesssales.com/stainless-steel-grades.html -

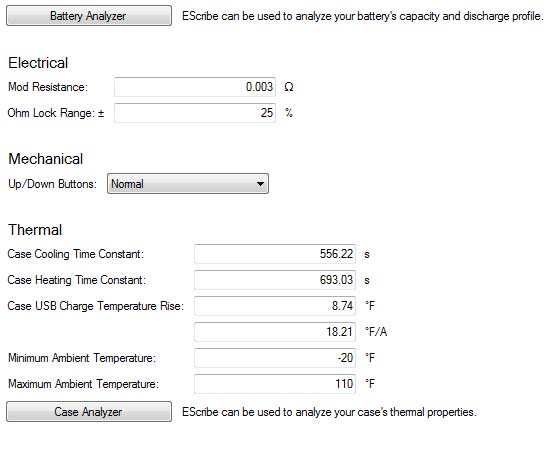

To all, Reuleaux just posted their 'official' standardized settings http://www.wismec.com/product/reuleaux-dna200

NOTE: It will completely erase all of your settings if you Upload to device. If your Mod is setup how you like it then I'd probably use these settings plus the appropriate Battery Analyzer settings; theirs is some generic 3x18650's. At the minimum I would back yours up: File / Save .. name it.

Official Battery and Case Analyzer numbers:

-

jj6404 said:

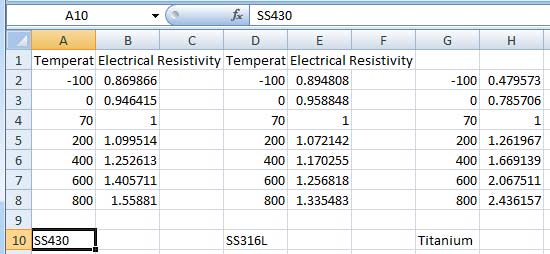

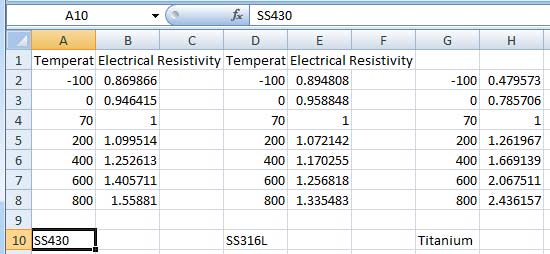

Jaquith, what do you think of 430 SS? It's resistivity seems to be much higher than 316 and 304. Might this translate to a more reliable and accurate temp control?

SS430 should be 'more accurate' looking at the differences between 400F~800F, but I haven't a clue about its oxidation, leaching, etc characteristics. SS430 Fe, <0.12% C, 16-18% Cr, <0.75% Ni, <1.0% Mn, <1.0% Si, <0.040% P, <0.030% S

Being straight up, I want to avoid Cr, Ni, Al, etc long-term. However, it's certainly a wire to play with in TC. I'm just having a hard time rationalizing Platinum wire because of its price. SS alloys in contrast appeal is it's cheap. Keep in mind, a Titanium coil will outlast the Atty itself... So price!? -

VapingBad said:

Could part of that just be that LiPos have no charge left below 3 V?

Did you run battery analyser to determin they were not going below 3V?

I have not done the tests, but would expect some 18650s and maybe LiFePos (not sure not used them) to go down that far. Maybe they did change the 2.85 V.

When the feature request was made for 2S it was implemented very quickly and I really can't see that there would have been separate algorithms for the cell limits.....

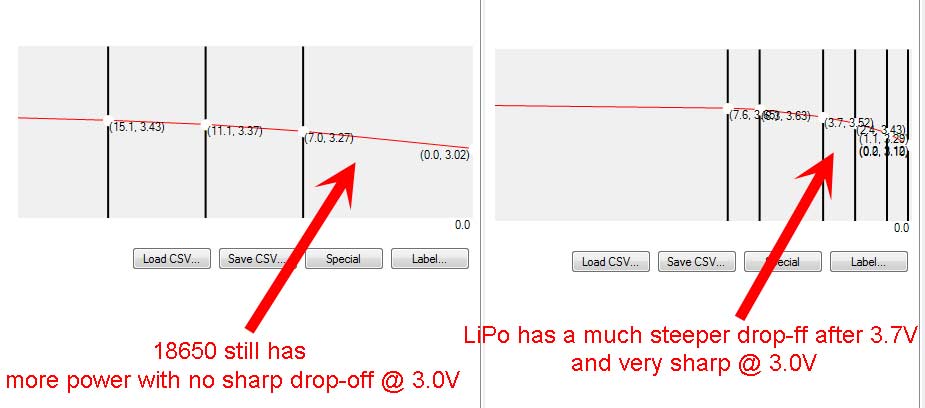

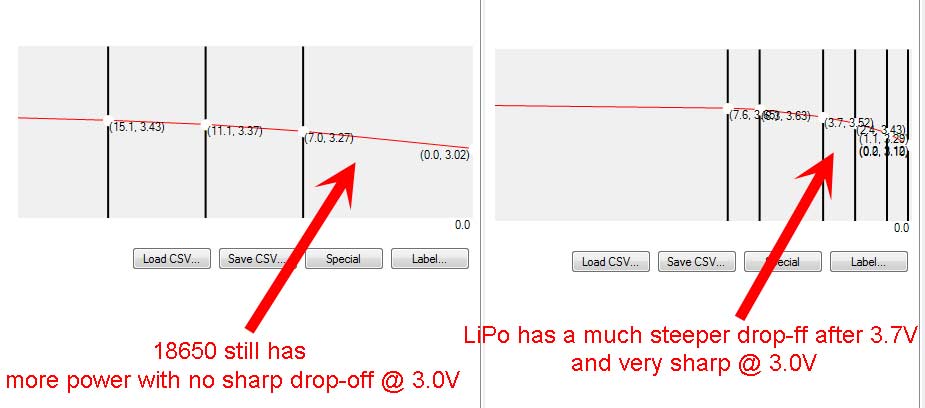

I can only tell you what I see and the 18650's in series have a markedly different power drop-off.

I'm not a battery expert but I'm observant. The 3.0V needs to be lowered to 2.5V~2.6V to accommodate 18650's .. they're clearly different drop-off's. Not to mention not every LiPo has the same specs nor cells. IDK allow an Expert mode to exceed especially lower limits. -

2.85V doesn't work or it wasn't transfered to the current firmware. I've run these same tests on several LiPo's 900 mAh, 1300, and 2000 .. plus a LiFePO4 and they're all different. Each has their own cells with different discharging. Obviously, the 3S is for LiPo's but the 2S seems to have 18650's in mind .. so the 3S needs a revamped firmware.

-

It's on red because Evolv has it set to a minimum of 3.0V obviously, not 2.85V (won't work) or 3.1V as you've been arguing all this time with me. Listen, I want my batteries to behave as they should and for a Meter and or percentage to be as accurate as possible. The Default LiPo battery looks dead on to a FullyMax, the data and in particular the discharge curve matches up. The only value that I want is the Mod's resistance all the other information is easy to obtain and can certainly can vary where different batteries are being used; different battery profiles and different Mod temperatures from the different batteries. Having all the data sets programmed only makes sense if there are no variables eg different batteries.

-

VapingBad said:

The default is just for a typical LiPo not for the Fullymax and I don't think there is any point setting the soft cut-off to 2.5 V when the hard cut-off is 2.85 V, unless it's changed since July https://forum.evolvapor.com/topic/67884-topic/?do=findComment&comment=911120

I would probably set it low for most IMR 18650s and can't understand where these cut off values over 3.1 V are coming from, unless there know there is a problem with a particular battery that some reseller has used and introduced it. But I would run the analyser to see the curve before making my mind up.

My 0% was 3.02V not the 3.1V that everyone else is getting .. because I did not use the 3.09V Default value. Oh yeah, the Default Battery Discharge certainly is the Fullymax FB900HP-3S Evolv sells here - http://www.evolvapor.com/dna200.php

Evolv needs to allow <3.0V Cut-off's to accommodate 18650 cells, and no not all LiPo's are the same (Capacity, Nominal Voltage, or Cut-Off). Using made-up numbers simply gives you a 'garbage-in garbage-out' erroneous charging and discharging not to mention a 'meter' that is off and frankly may never see a eg 100% charged.

I'm using my values. I do understand the cut-off of 3.0V vs battery's 2.5V reduces the (mAh) potential of the 18650's with a sub-3V cut-off's. -

LG HG2 Battery Profile (CSV) - http://www.filedropper.com/3slghg2batteryprofile

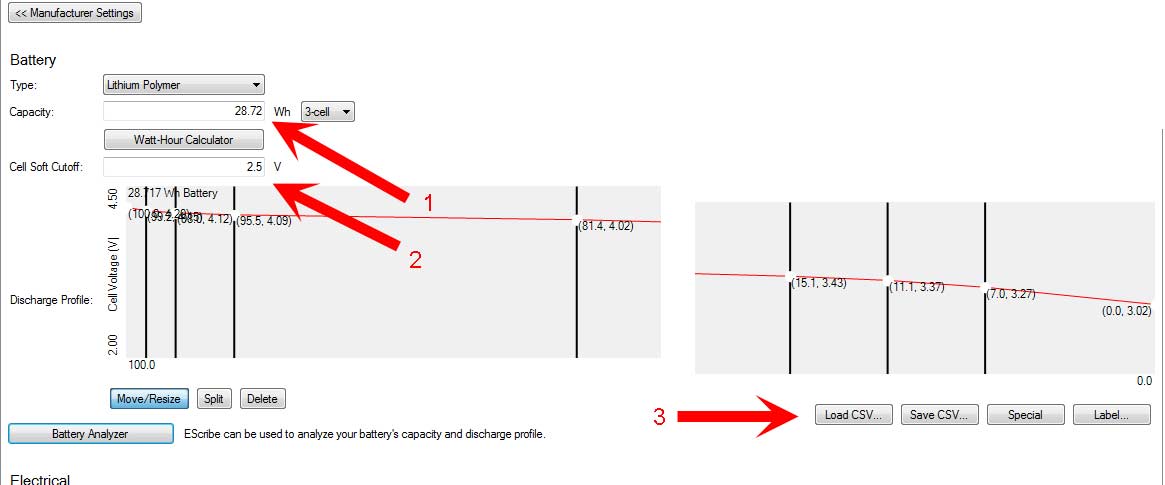

I ran the tests twice using all of the correct LG HG2 values; Capacity 3000 mAh, Nominal Voltage 3*3.6V=10.8V, and the correct 2.5V Cut-off. Both tests were rather close the 28.72 Wh vs the theoretical 32.4 Wh was a little disappointing, and even 31.86 Wh (2950*10.8) would have been perhaps expected.

The batteries are all new and married; initial charge, full discharge, recharged and then tested.

The Default 3S (3 cell) are from Evolv's FullyMax FB900HP-3S: Capacity 900 mAh, Nominal Voltage 3*3.7V 11.1, and a 3.0V Cut-off. Specs - http://www.asaseletricas.com.br/loja/images/Data%20sheet%20for%20A0-FB900HP-1S%2030C.pdf

It's a simple process, Input 3 numbers reverent to the specs of your batteries, and run the test .. then Save to your device. -

Use whatever you want, the 3.09V and 11.1V is the Evolv tested spec from FullyMax FB900HP-3S a LiPo battery, and not any 18650 in mind. Search FB900HP-3S cutoff voltage...it's an error.

-

My Vapor Shark is a 9/19/2015 imprinted device, I waited because of the finish issues to be sorted out. Wow that's unfortunate, but Vapor Shark is a very good company; contact them for an RMA. It might be worth a check and device reboot and if necessary reinstall the firmware. I've tried both 480° F and 250° C on two different Atty's a single and dual and they vaped identical.

-

Using both Celsius and Fahrenheit right now, and it works for me. I'm using the latest Escribe and Firmware.

-

Samsung 25R's (cyan) Nominal 3.6V, 2500 mAh, 2.5V Cut-off. Specs http://www.powerstream.com/p/INR18650-25R-datasheet.pdf

-

Depending upon the voltage drop, sag, 3.09 translates to a considerably higher actuall / no load voltage. LG tested the batteries to the 2.5V @10A & 20A. You're not the only one I've ran across doing that, I found someone posting an LG HG2 from Germany. Tomorrow, I'll post. :-)

-

I looked at the file, and there is no 2.6V or 2.8V .. just the 3.09V LiPo default. I ran the Samsung 25R's and tomorrow I'll run the LG HG2 (3.6V Nominal, 3000mAh, 2.5V Cut-off) and post the CSV. I've read the 2950 mAh, etc, etc .. I'm running the batteries to spec; ref http://keeppower.com.ua/download/2015-06/datasheet-LG_INR18650HG2-1.pdf

-

I've got to point something out here, just an observation, everyone seems to be using the standard LiPo Cut-Off (3.09 - 3.XX V) .. while I'm certain it works, most 18650's have a Cut-Off of 2.5~2.6V (refer to you battery's full specs). Example, under NO LOAD my low 18650 might be 3.5V but under LOAD 2.5~2.8V.

Therefore, all of these posted TXT or CSV Battery files for 18650's as best as I understand batteries, are too high (off) and a shortened use cycle. Please enlighten me if I'm wrong here, but AFAIK I'm correct. It kinda defeats using a 3,000 mAh battery...

Thanks! -

Jalcide said:

Related question for the group... Steam Engine's 316 and 316L look almost identical, except for a tiny change in the 2nd decimal place of that last breakpoint on the curve.

Will it matter?

Being honest, I don't know, and as I mentioned before .. there are several different alloy mixes for SS316L, SS317L, SS304, etc all of which are SAE standards and China follows primarily GB standards; close not exact. Therefore, purchasing eg UD SS wire from China of some other than actual 'SS316L' or 'SS317L' is the reason I'm constantly modifying the CSV files. Conversion - http://www.iron-foundry.com/stainless-steel-grades.html

To date, the only Steam Engine CSV file that worked 'out of the box' was their Titanium Grade 1.

So will it matter .. chances are yes. I certainly would run the cotton test before finalizing any build with NEW wire! My opinion, I really doubt SS wire will be anything more than a 'fad' and I feel Titanium or some alloy of Titanium with a middle of the row TCR is going to be it for TC or at least the current approach of (Resistance, Temperature) TC.

Now I've considered Platinum wire, it's a noble metal, it won't oxidize, and it has a high meting point similar to Titanium. HOWEVER, it's DAMN expensive! LOL people complain about the cost of Titanium.

BTW .. by far Titanium is way better in every way over SS, I'm just messing around with SS out of curiosity and fun. -

It should but it won't be exact, G-plat / SS317L is close but not exact to SS316L. The biggest difference is between SS304 and SS316L / SS317L wire.

-

Hard to say, the differences are small, all work. 550F - 600F should be hot. I posted V3 for those who want a cooler vape.

On UD I personally prefer the V4 and on 'Grade D' SS316L from Uwell ie Crown I used V3 and of the 3.5 vs 3.25 on the 'Crown' preferred 3.25.

I think the 'problem' or at least it is to me, is the preheat. When I both use a lower 1.5~2.5 Punch AND 0.5 Seconds AND a lower Preheat wattage than the Power wattage then I had NO BURNING or aka over-heating.

When someone says V3 too cool and V4 too hot at higher temps .. then the answer is obviously fine tune the hotter temps and find a happy medium.

Frankly and IMHO Evolv needs to revamp the Preheat; example Preheat power (wattage) as a percentage of the Power that the user sets dynamically; 10%-200%. The reason is it's, to me, a PITA to change one value easily BUT the other requires a PC intervention to access!

- David -

Easy enough, here's version 3.5; it's lower temps are unchanged, but the higher temps are an average of V3 and V4 .. hence V3.5 - http://www.filedropper.com/dna200-ud-ss316ldjaquithv35

In addition, V3.25 is an average of V3 and V3.5 at the higher temps - http://www.filedropper.com/dna200-ud-ss316ldjaquithv325

Let me know! BTW on SS I try to keep the preheat between 2-3; I'm using a 1.9 at 0.5 seconds with a 120% of the set wattage. -

Yeah that's the aggravating thing about SS316L, is there are at least 4 SAE alloys but UD is from China and they don't have an SAE standard. Frankly it has gotten to the point where you have to test and make adjustments for each wire. What's needed is a tool that can create CSV files .. DNA 200 Mod plus a built-in temperature probe connected to a computer. If the temperature seems too high or too low then let me know and I'll make some adjustments. Otherwise if you edit the file to increase the desired temperature increase the resistance by approximately 0.05 Ohm and test. The temperature should be close up to 460° F but the 500° to 600° F might be a little off. If I need to re-upload it's not a problem it takes no time. Let me know! :-)

-

I guess the files expired, but when I just re-uploaded the identical files now the old links work. Sorry about that! Version 3 - http://www.filedropper.com/dna200-ud-ss316ldjaquithv3 Version 4 - http://www.filedropper.com/dna200-ud-ss316ldjaquithv4

SS316L Help

in General Discussion

Posted

LOL about the only quasi accurate CSV is their Titanium Grade 1 profile. I use Titan Wires and I'd recommend 24 (25 gauge actual after polishing), and yep I space them all. Probably not as much as you might think. Here's an example of one that was totally gunked up but I cleaned by 20W, dual, and rinsed under water with a toothbrush http://i.imgur.com/8WKpCNHh.jpg Stainless Steel is a pain, I'm about done with it, and it's soooo much easier having 1 TC wire to deal with. Titan Wires http://titanwires.com/titanium-wire works great on all my Titanium Mods.