Rob_H

-

Posts

84 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Downloads

Posts posted by Rob_H

-

-

You should be able to find the screen with a long whip online. They are standard lengths and available with a little searching.

-

Yah ive got the bug too. Mostly if they come in Hana enclosures but a couple that do not (6 that do). I want to get a couple of the 60w's going. I have one Dna200 and one Dna133, not interested in the 250 or the 75 to much.

-

I have not heard of anyone getting any model of them yet.

-

Same here, very interested in a Dna60 model but want to see what it looks like. Mostly button placement, I imagine it using on board buttons with the screen stretched out below the up/down buttons or on the side like Hana does on their mods. Either way very curious to see something.

-

-

I use a 40w for wiring up boards and install. I have a 30w that I use for components but that does not get used very often. The 40w I can get on and off the board quickly with good joints. I think the recommended is 30w in most cases but I find that too be too cool.

-

After taking a normal puff does the meter rise?

-

What would be the hurdle to overcome doing this? I would think you would have to go into escribe and change the watt hours for the battery being used. Other than that everything should be the same.

-

Kayfun 5 on my Hana and 22mm Avocado on my 133.

-

turbocad6 said:

thanks brother, guess it's not so obvious in those pics, but that's also a bottom feeder with a full 8.5ml bottle on board

I did see that. Nice you were able to make it so small. Where are the buttons at? I see where the fire button is but what about the others? -

turbocad6 said:

loving this dna60, really allows for building a tiny mod with a lot of power and the latest greatest temperature control algorithms, very smooth with ss316

Thats awesome!

-

KTMRider said:

I've bought and sold a few DNA40's (and a couple of SX350 mods) but I've kept all my DNA200 and DNA75 mods.

Here's 2 DNA40's I built and still use (Cloupor clone and Fasttech mini clone). The 2 other DNA40's are VS DNA40 and rDNA40:

Those are nice mods you did I think I may have seen these over on ECF a long time ago. Not in this picture is a Dna133 I did in a Modcrate enclosure its one page back from where we are. And a Hana V4 mini Dna40.

-

Frogmod said:

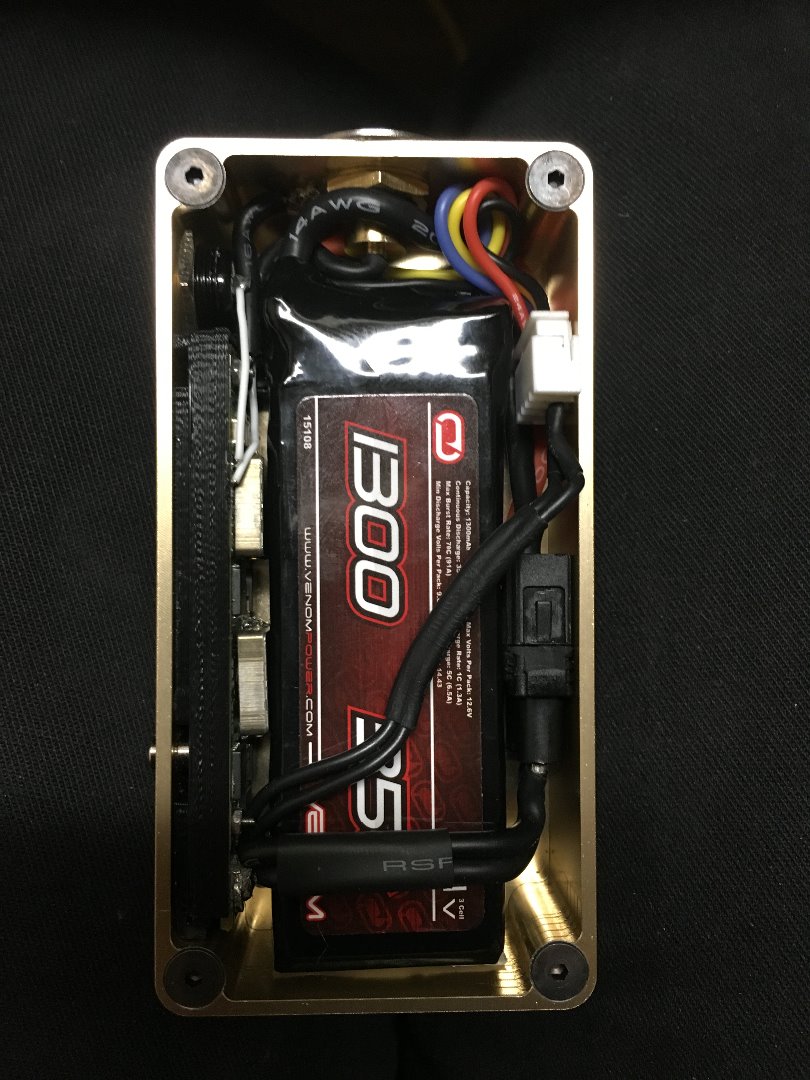

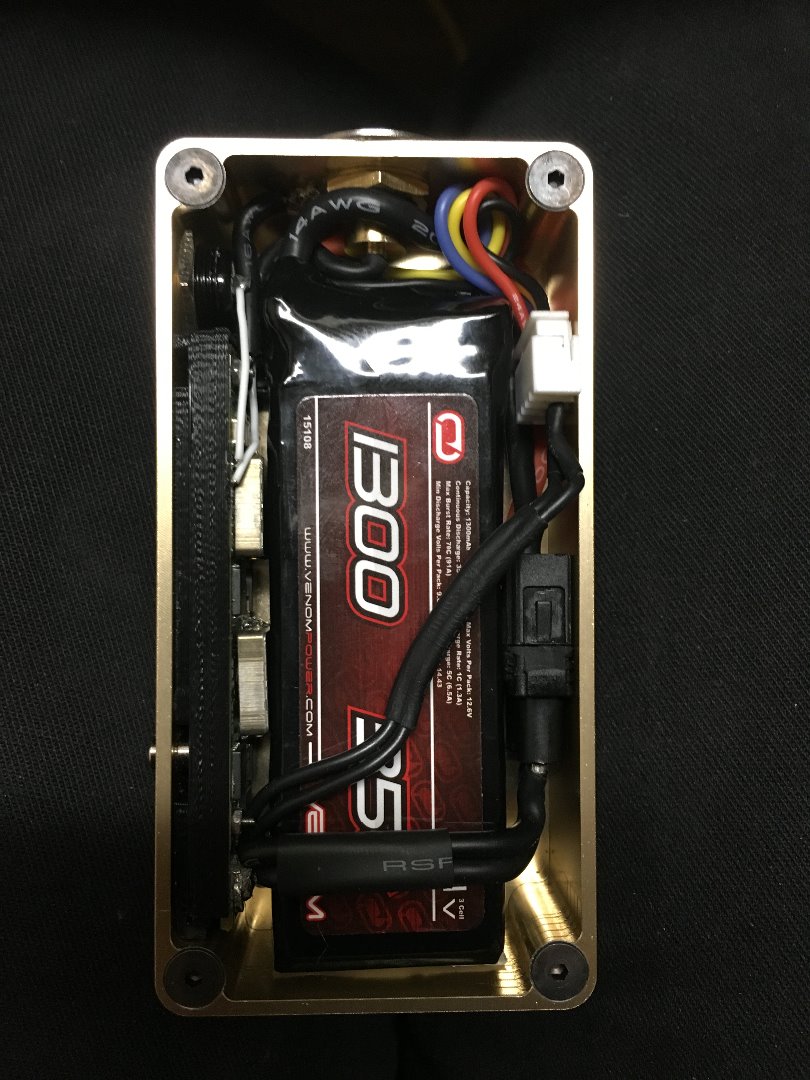

last week a customer at the vape shop wanted a anodize gold dna 200 box mod I was about to install one but the 1/4Kw chip came out. He has no clue that he's getting this chip. I can already see him rubbing it in everyone's face LOL!!! This is how I build my mods with no glue except to hold the screen in.

Thats really nice! And you gave away your Dna250! -

KTMRider said:

I used electrical tape (3M) and a piece of closed cell foam between the board and screen.

Ok I understand thank you. -

KTMRider said:

I have 5 DNA200, 3 DNA75 and 4 DNA40 in rotation. None of my mods are set higher than 30w and most are set to 25w.

LOL I have two Dna200's and 4 Dna40's and the highest any of them are set is 35w. I plan on modding out two of my Hana Dna40's and put Dna60's in them so I can still vape under 35w haha. -

I thought I had read it was a 1amp board that comes with the Dna60. You have the option when purchasing the board to get the charger or not. You need it to work with Escribe I am pretty sure.

-

Alcaideariel12 said:

Hey Guys.

I'm new to the forum and I just wanted to share.

Nice collection Got any Dna40's or just the 200's and 75's.

Got any Dna40's or just the 200's and 75's.

-

KTMRider said:

I had the same issue with my Hana v200 last year. They answered a couple of emails and then ignored me. Evolv stepped up and sent me a new screen.

Here's how I bent the ribbon:

How did you manage getting the screen into place upon reassembly? I have to reinstall a board that was faulty in my V200. Waiting for Evolv to repair or replace the old one, they have only had it for a few days but was wondering what the best approach would be. The original screen was hot glued in place. Was thinking maybe there was a better way. -

soulseek said:

Finally they're doing that! However, are they putting the DNA60 in the same case as the DNA200? In that case, it would be worth it just making a smaller one on your own.

The reference mod enclosure is pretty tiny. What enclosure were you thinking of using. I would imagine they would mill the reference enclosure to accept the dna60 and use the on board buttons. And maybe make it a little shorter? Although a 900mah lipo is about as tall as a 18650 in a sled so....... -

James said:

aonoukraine, I am curious, why do you say according to the core wire?

I may be extremely tired from coding, but I believe you'd do a custom curve in Steam Engine with the two wires considered to be electrically in parallel.

Not trying to steal the thread from OP but I have to ask. Would this work with a Kanthal core and ni200 wrap, making a custom curve or is the two different materials not something the board would deal with. -

I see on the main Evolv page they are building mods now in the Reference Mod enclosure. Dna250/200/75/60 and the prices are on point IMO. I will be going after a 60 I think, having two Dna200's a tiny little 60 will be pretty nice.

-

Oh yah I forgot about that.

Oh well

-

I would like to see a firmware upgrade on the Dna133. Seems we could safely get 9v from a 133 configuration. I like to build above .50 and sometimes above 1ohm, would be nice to get a full 9v.

Any talk about this at all? -

maawolfe36 said:

Thanks, I hadn't thought of that. All I have in SS right now is 24g and 32g, bought them to make some high-power/low-resistance claptons, but with 24g it looks like I'd need way too many wraps to get to 0.4 ohms so I guess I'll just have to use this stuff in power mode and get some thinner wire for TC mode.

Just out of curiosity, what settings do you use for your SS coils in TC? I'm pretty new to TC in general, and I don't really even know where to begin with setting the temp and watts, though I seem to recall reading somewhere that cotton begins to burn around 420F.

So I am not 100% sold on pre-heat yet and I think I prefer not to have any. I have 4 profiles set up for SS. 2 with pre heat that is 10 to 20w higher than my normal watts. 2 with no pre heat.

In a tank I am running .63 ohms spaced. Pre heat at 40 then back to 30w, with a temp setting around 450-480 depending upon my mood.

In a dripper I am running .50 tight spaced. Pre heat at 60 then back to 40w, with a temp setting starting at 480 - 520 depending on my mood.

The other two profiles have the pre heat set the same as the normal vape time so instead of 40w it would be preheat 30 and wattage set at 30. and the same on the other.

I am locking ohms in every time. And the board asks me if it is a new coil every time. Once up and running it does take a few minutes for things to calm down a little vaping for a few minutes. And once it does it is very rock solid and I know exactly what to expect. If I need more flavor and vapor I just turn the temp up 10 degrees each time till I get what I am after.

I think if you take the 32 gauge and make a tight twisted wire from it you can get to where you want to be. Keep it normal no parallel build at least for right now. Space the first builds so you can get a good feel of whats working right and build from there.

Screen replacement for a VaporShark DNA200

in General Discussion

Posted

Need to know what length the whip is first and ill see what I can come up with. Screens are sourced parts as with everything else. Here is a good place to start the search and if OP could measure the length it would help out allot.

Dna200 uses MI12832DO-W5 asfaik

http://www.multi-inno.com/oled.asp