-

Posts

84 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Posts posted by Bapgood

-

-

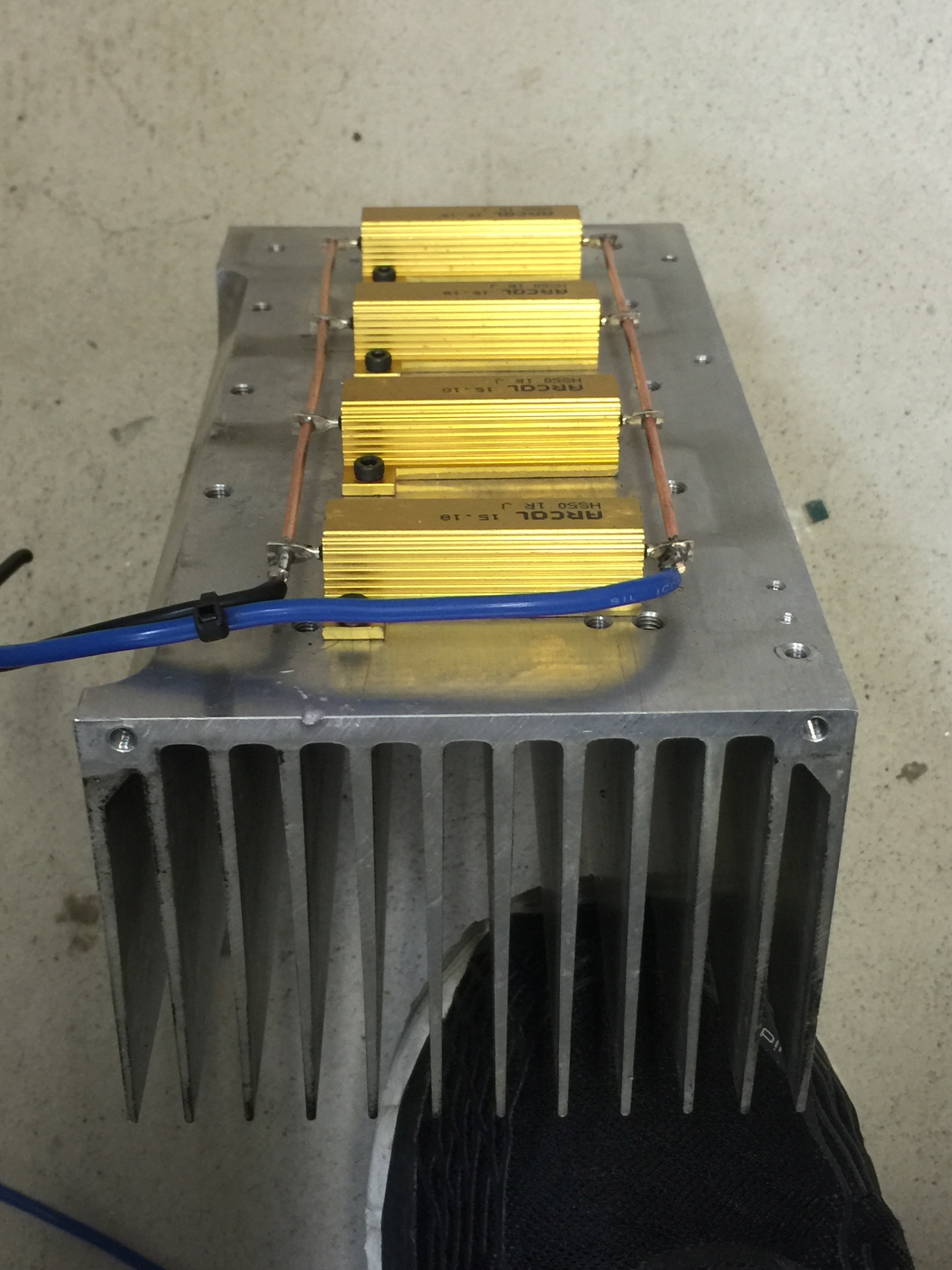

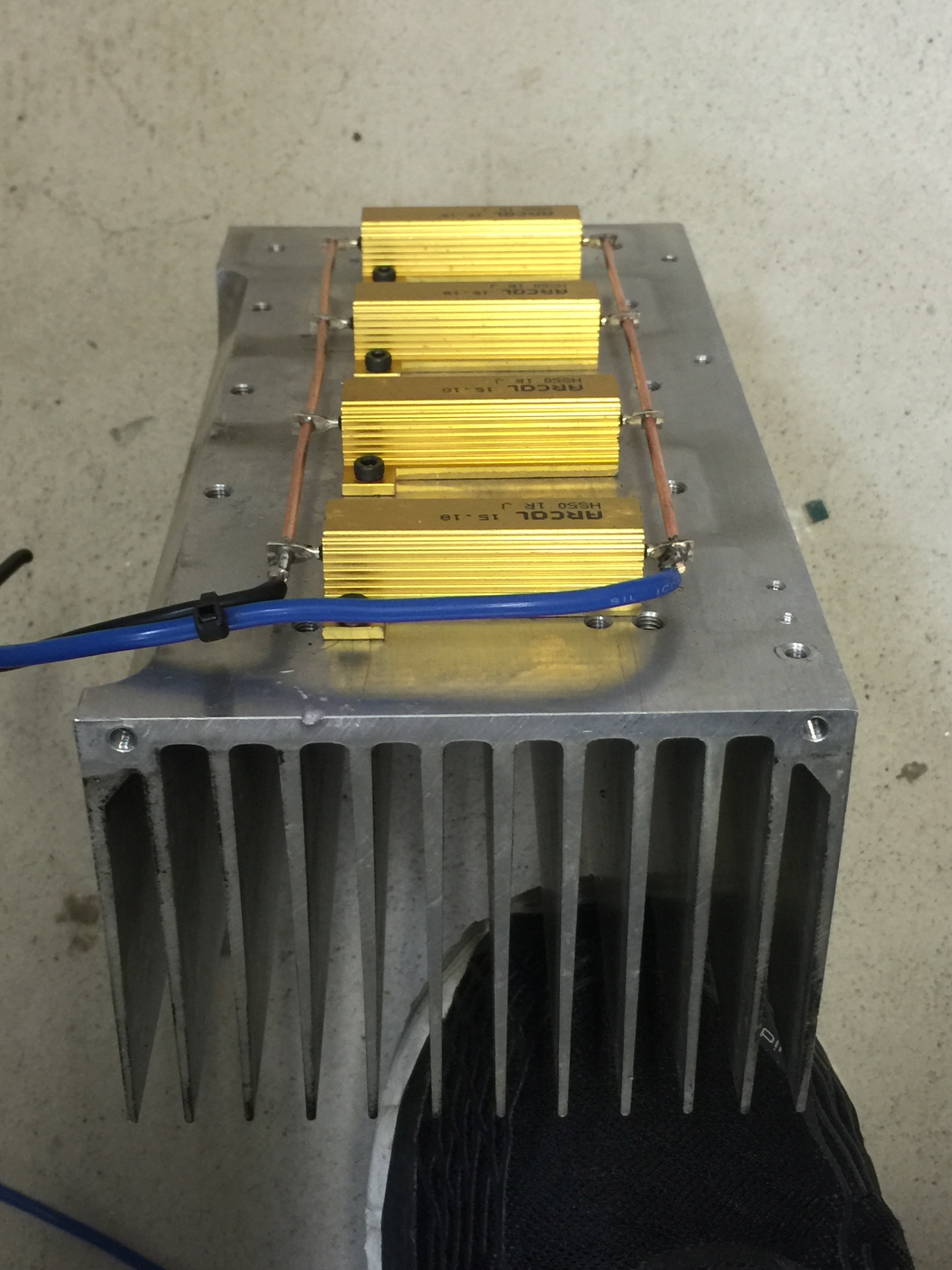

Big thanks to a friend for sourcing the very adequate heat sink!!!

Been kicking around a few ideas for the 510 connection. But please show me your solutions for some possible inspiration

-

Yes as stated the latest version of EScribe gives you the option to change this.

-

What do you have the charging brightness set at in EScribe?

-

First question is what is the reason you want to control the fire switch with a mosfet?

-

How I recall it being explained to me is:

Short Version:

Temperature = Flavor

Wattage = Vapor

Longer Version:

You wan't to set your temp to where your juice vaporizes to your liking. Juice will vaporize at a specific temperature based on its makeup, once it hits that temp adjusting the temp higher can change the taste of the juice and etc. up until the temp the juice turns nasty and harmful. VG and PG vaporize at different temps so there is not really one temp that works for every juice or even a temp that everyone prefers with the same juice. Personal preferences are always different as are builds and etc.

Then wattage can be used to adjust the amount of vapor that is produced. Higher wattage = more vapor....lower = less.

However it has been my experience that it is difficult to build a setup to efficiently achieve this. There are many variables in a setup that can effect all of this and right now I think the TC tech is further ahead of atomizer tech which can not properly take advantage. So right now we basically find a build to suit our liking and adjust both temp and wattage to maximize the build/setup based on our preferences. Slight adjustments can be made with temp and wattage to fine tune, however larger changes are made by changing the build/setup. -

Submit a ticket to Evolv and they can tell you your options. http://helpdesk.evolvapor.com/index.php?a=add

-

digatel said:

Are these EVOLV 510's available to the public now or in the future?

I believe they will be available sometime in the future. -

lexalove said:

Thanks Bap & Nick... good information to know.

I didn't see any 3D Models specific to the 510 or are they in the model for the reference case? (Only have Solid Works at work so can't open it at the moment since I'm at home).

Yes the 510 parts are in the 3D files -

lexalove said:

I've never seen or owned one of the original reference mods so can someone explain to me what's the deal with the 510 connectors on these mods? What is it about the design that makes it so much better, than say a FDV item, which is what I use on all the mods I sell including the 3D printed reference mod I've built?

Then the next question, of course, assuming they are as superior as people are saying will they be made available to us mere mortals?

Cheers

3 things of the Evolv 510 stand out to me:

- Spring Force (this is the main one, much higher spring force than any 510 I have seen)

- Copper Center Pin (I believe they might be having these coated now for even better performance)

- Ultem 1000 Insulator Material (will stand up to the high heat produced by high wattage vaping)

I believe Evolv plans to make their 510's available at some point in the future. Just like case design, Evolv has made the design, specs, materials available and free for anyone to use. https://forum.evolvapor.com/topic/68495-topic/?do=findComment&comment=915975 -

promod2000avenger said:

You stated all 4 of these are from EVOLV.

So are you saying EVOLV made 4 different size reference enclosures ?

Not that I knew of.

They only made 1 size.

The small 900mah one.

Maybe I am incorrect.

If I am please correct me.

Walt

If this in reference to my post...I don't believe I said there was 4 different sizes, or didn't mean to anyway.

Only that the very early one is slightly shorter. To my knowledge there is only one size. -

I would suggest hitting up Evolv for possible RMA.

-

The warranty service message typically means the mod needs to go back to the manufacturer. Especially if it died completely.

Will EScribe still recognize it?

-

Are there even still atty's that use bottom air and need the air channels....lol

I'm sure there is, but nothing that I have

-

I think its funny when people say they don't like the look of the Evolv 510. Once you put an atty on it, it basically disappears....lol.

Plus the Evolv 510 is by far the best 510 I have seen. Especially for TC where a solid connection is so important.

-

Scoopy I sent you a PM.

-

The one is the early version of the reference mod.

Differences:

- They didn't have the slight recessed portion all the way around the middle of the mod.

- The lower two screws set a little more proud.

- The screen was set back from the face further.

- The 510 was quite a bit different, but the same basic design/concept.

- The overall height was a little bit shorter.

-

Nope not 3D printed....they all came from Evolv

-

scoopy said:

Bapgood. .....I was thinking of having my reference mod painted somehow. .....what do you recommend. ....any certain process or way to have a finish just like yours get done to mine

The tolerances on the Evolv reference mod are extremely tight!!!

Even with the Cerakote (which is a pretty thin coating). I have to:

- Mask out the button holes so the buttons fit.

- I use my lathe to take just a little bit off the OD of the 510.

- And be careful not to get too much of the coating on the backside of the halves where the two halves interlock.

I'm pretty sure powder coating would be too thick. I also think a typical rattle can paint job would also be too thick. Anodizing would probably be ok....but would require more masking than the Ceracoat. -

All are Evolv made 510's

I know I'm not the only one around here with one of these

-

All Evolv reference mods. Cerakoted cobalt and tungsten. One is different than the others. Who knows what the difference is?

-

As a general rule...If EScribe no longer recognizes the mod/dna its time to contact the manufacturer of the mod or Evolv if you purchased the dna and built the mod.

-

Droopydroors you said you got it fixed. What was the solution?

-

Turbocad will be answering pm's for weeks....lol

-

You are correct, it's not a profile setting. However I wonder if it could be.

I would be interested to hear if adjusting the punch and preheat time help with your situation.

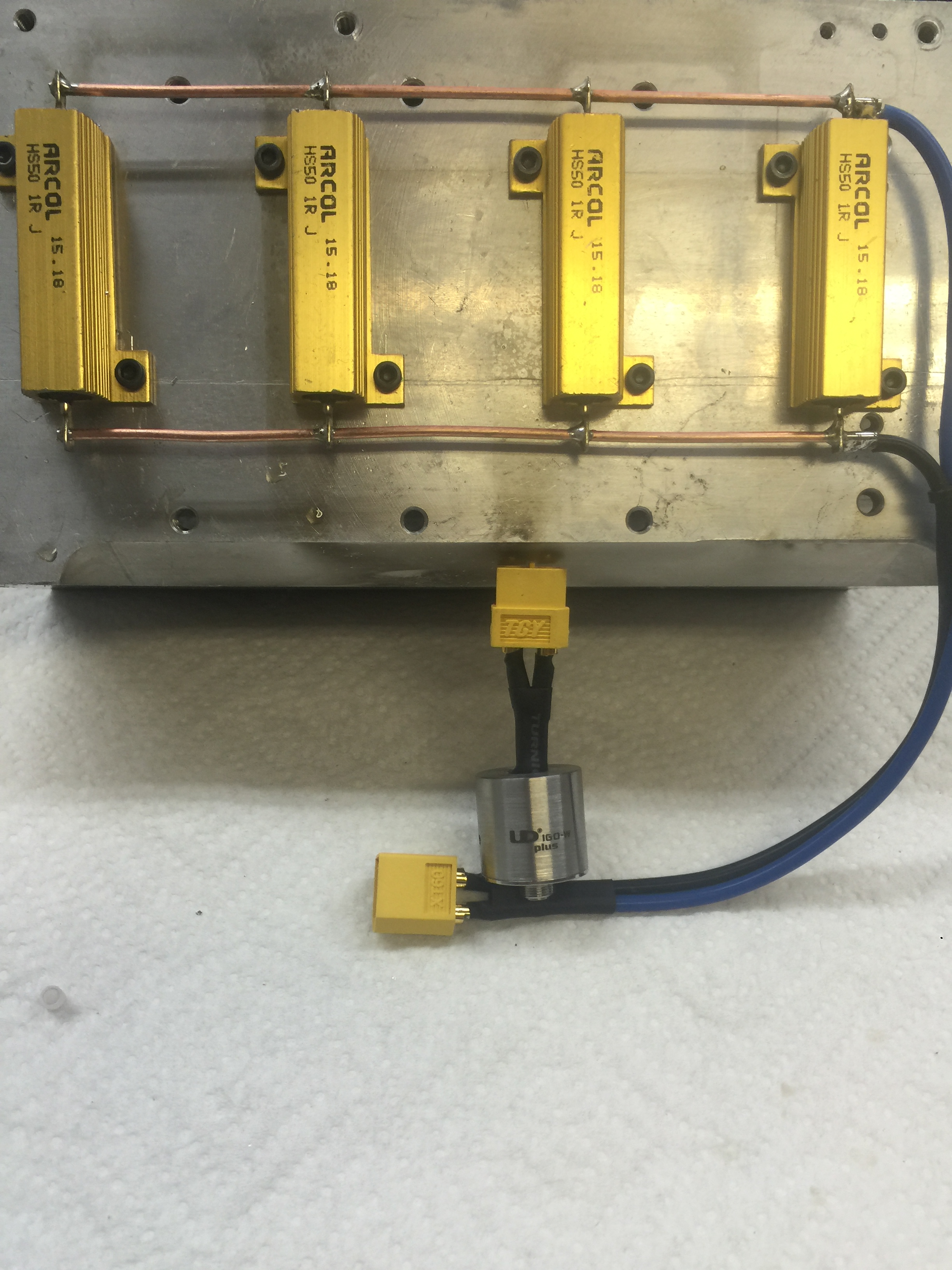

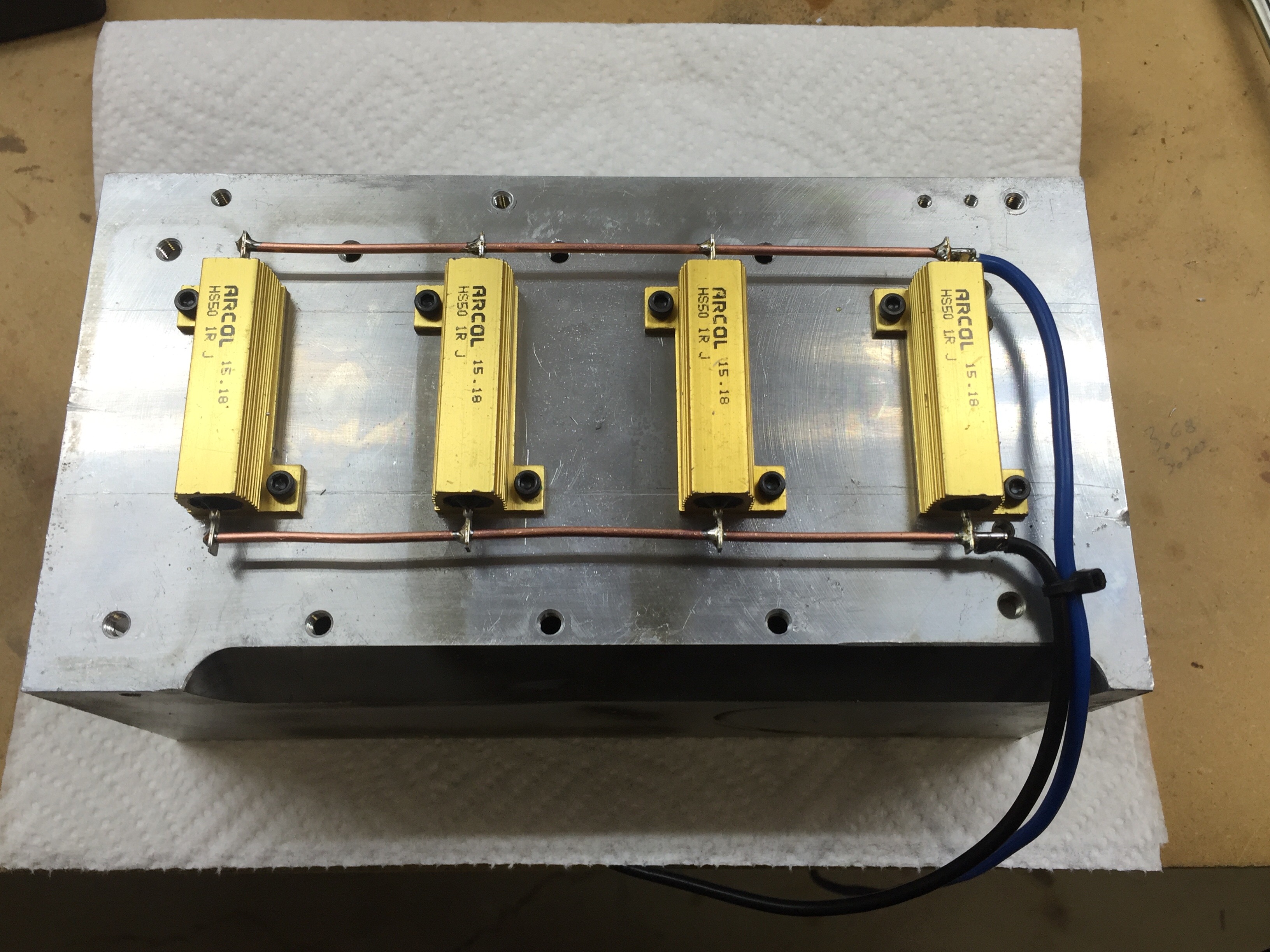

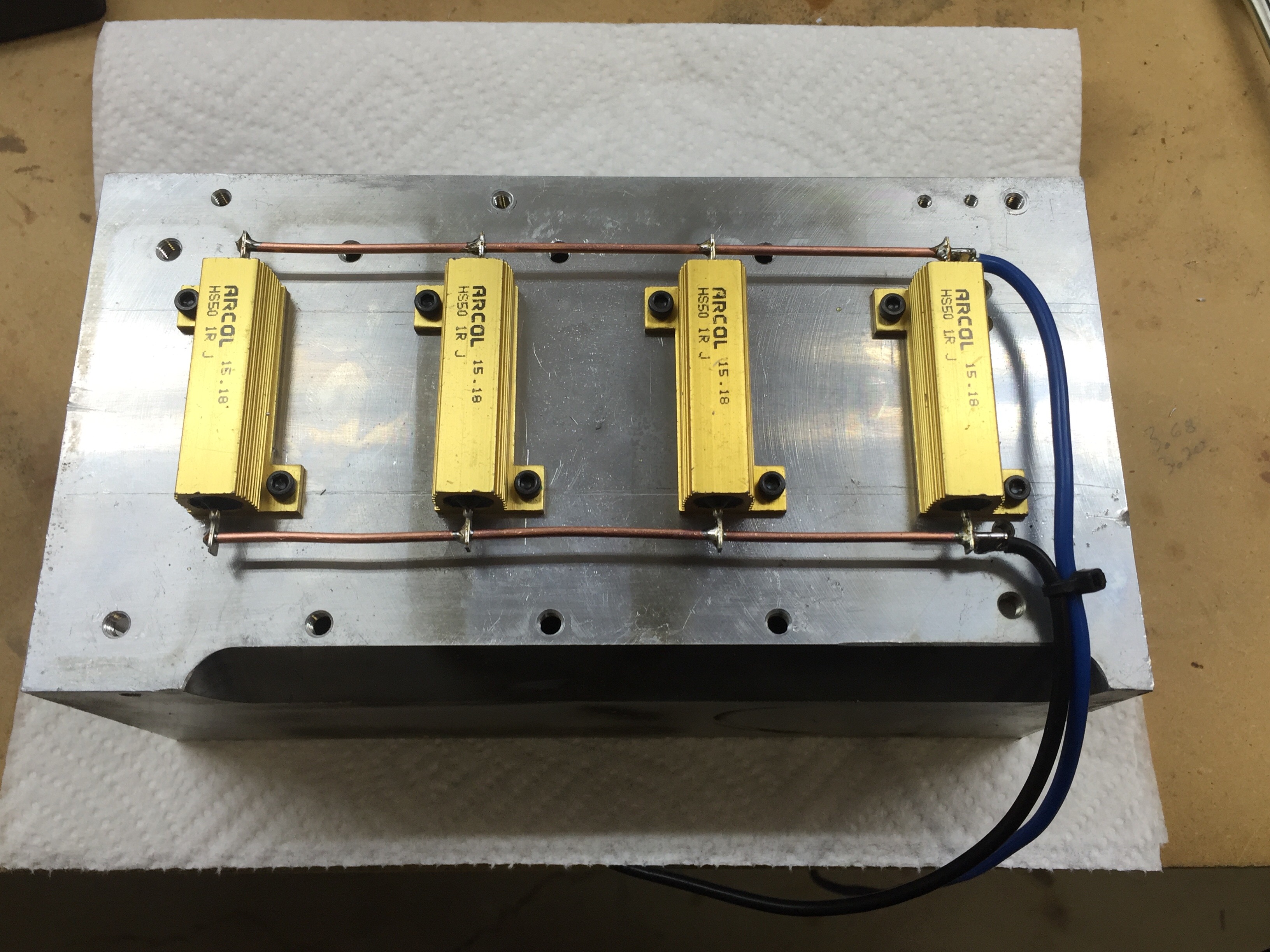

Battery test rig almost done. Show me what you have done for the 510 connection on yours.

in DNA 200 and 250

Posted

Haha yeah I was overthinking it. For some reason I was thinking the connection would need to handle a lot of heat. But as long as the connection is good then there shouldn't be a concern for excessive heat.

So I just used a cheap dripper