mikepetro

-

Posts

190 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Posts posted by mikepetro

-

-

My 2 cents, this is a 200w board, it is what you knowingly bought going in, If 200w isnt enough to drive your xyz coil then you have two choices 1)take a wee bit of mass out of your coil, 2) find another mod, perhaps a non-regulated 60C lipo mod.

I am not Evolv, however if it were my product, one which I built a ton of safety features in to protect folks against the bad stuff that can happens, I would not sacrifice my safety margin, or my builtin service factor just to satisfy the 1% of customers who want to push it beyond its intended safe design

I think the reality is that you could put out a 300w, or even a 500w mod, and there will be the adventurous few who will ask for 10% more power to push those mods even further.

Evolv has always placed safety #1 in their designs. I sincerely hope they never compromise that. -

I tried running case analyzer on this same case today, and while it runs a long time, it never completed. Rather than giving me values and offering to save them, it just went back to Record/Start screen.

I think this part is a red herring, ie my mistake. I suspect device #1 had too much of a charge to adequately complete the test. I suspect it reached max charge and the test aborted. It would be nice to have an informational message in this case. I could have proved it out in DM but I already had device #2 in the case analyzer process before this possibility occurred to me.

Anyway, the other questions are still very valid:- Why did 2 devices lose their thermal settings and revert to default?

- Why wont "Case Cooling Time Constant" go above 1000 now, when clearly it used to?

- Why are analyzer results so different now than they were 6 months ago? The environment is the same (same workbench etc) except that ambient temp might have been 1 or 2 degrees cooler last October.

And I guess another question is, how much difference does it really make. I know the purpose of this is to more accurately determine room temp, and consequently more accurate TC, but how much of a difference does it really make? For example, I have no clue when it defaulted those settings, nothing ever stood out to me, but then again I have switched attys too so it could have been masked by that. -

Back in October of last year I produced a couple of Mods and ran case analyzer on them. All of them had values similar to this one captured on Nov 4th 2015:

I was playing with the exact same case today, which has gone through all of the firmware/software updates that have been made available since then, and it appears that the Thermal values got reset to default somewhere along the way. This is what it showed today:

I tried running case analyzer on this same case today, and while it runs a long time, it never completed. Rather than giving me values and offering to save them, it just went back to Record/Start screen.

If I manually try to plug in the old values it always caps the "Case Cooling Time Constant" at 1000 and wont allow anything higher.

Is this normal behavior now?

Are my other old settings still valid if Case Cooling Time Constant is now capped at 1000?

I am running Case Analyzer on a 2nd identical device right now. It too got reset to default values at some point.

Escribe v1.0.4.2

Case is custom milled 6061 billet, based on Evolv Reference design but larger. Enclosure weight = 98g

-

In case analyzer, when you first start it asks for ambient room temp.

If the ambient room temp changes a degree or two during the test, which is quite long, does it invalidate the test? -

It would be nice if Evolv released Power charts, similar to the original ones in the specs, that represented a 2S configuration.

-

VapingBad said:

I don't like deleting or moderating posts so can we please keep it civil, even if another post got your back up.

Thank you VB! -

blueridgedog said:

I have had five of five boards go bad back in the DNA40 days...prior to putting them in a mod...just bench testing.

That said there is some atomizer interaction that seems to trigger fuse issues. I have not seen enough of it to put a finger on.

Yeah the screen scramble thing with the DNA40 was a bummer until they figured it out. Probably Evolv's darkest days.

With the DNA200 though, I have 8 of them, 2 directly from Evolv, and 6 that I built myself to Evolv spec. Haven't had the first problem out of any of them. Well... except for the Evolv Beta Mod that I damaged when I dropped it on concrete and one of inductors fell off, but that was my bad and Evolv replaced it anyway.

I suspect that if a Mod is truly built to Evolv specs (no shortcuts) it will perform well.

From what I have seen though, many of DNA200s being imported do not build to Evolv specs, and many of them get reported for problems pretty regularly. Even domestic Modders have had design issues implementing the board. Just take look through the threads in this forum to see that.

Even on well built Mods though, there is this whole blown fuse thing going on that I dont think anyone has identified direct cause and effect yet. As BRD says, it may well be an atty interaction of some sort.

Anyway, the DNA200 technology is sound in my opinion, as long as it is implemented correctly.

I have built several, and will build several more, and I am confident I wont wind up with the lemon.

-

Yes, there is no harm in that, in fact that is better than fully discharging the batteries, they will last longer that way.

-

blueridgedog said:

After finding the Aromamizer, I ditched all others (put six of them in rotation and put my prior six GTs in the junk bucket).

Ditto, except I bypassed the junk bucket and all other attys either got PIFd or went in the trash. -

I gotta be honest, I have yet to hear of Evolv denying a warranty. I am aware of literally hundreds of Mods that were home DIY, Evolv never squawked about warranty, and many times it was clearly user error.

I dropped my mod and broke it, Evolv replaced the board anyway, and I was upfront about dropping it.

Throughout this whole forum here, I dont think I have ever heard of a claim being denied. -

Make sure you know your Machinist well. Delays are common. Mine quoted 6 weeks and it will wind up about 5 months.

If delivery timing is important, consider insisting upon a penalty (discount) for late delivery. I wish I had........ -

The 510s were included in the kit.

-

justchil said:

Are you guys firing until the soft cutoff hits or what?

Battery Analyzer does the firing, and yes, that is basically what it does. -

Bumping this up.

There are 23 Battery Results posted so far, the battery results are on the right hand tab visible at the bottom.

https://goo.gl/b33IPB

Form to enter a Battery Test Result:

https://goo.gl/IP9iSA -

This was off the one you polished for me. -

Alex faught said:

So if one were to buy a brand new device, what version would it have on it? Is the escribe software download on the internet up to date?

The firmware version installed on new devices will depend on:- Did the Mod Maker update the firmware

- If not, then when was the board purchased

There are two version available on the web, the RELEASE version, which is considered to be the most tested and stable. And the EARLY FIRMWARE version which is available in the first post of this thread. It has the latest fixes and feature enhancements. I run it on 4 devices and have not encountered any issues with it. -

When you power it up is it the same color? I have heard that the new screens Evolv is sourcing is a different color.

-

Love the way this is developing.

Added it to my DNA200 Resources Page -

Awesome contribution, thank you!

-

Chris_159 said:

Have anyone used a turnigy lipo. Are they any good?

They arent bad at all, but their QC is somewhat lacking and I have heard of people getting bad ones. I have several and all of mine are comparable with most of the other Lipos I see. -

Keep in mind that during the Holiday season (as in - right now) almost all mail systems globally slow down a bit too.

-

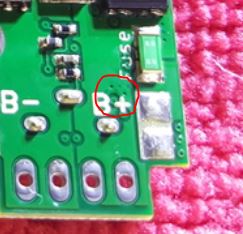

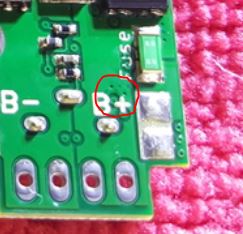

Just a stab in the dark here:

Notice how the positive wire is soldered.

It "appears" that the positive wire is directly over the top of some "vias".

Could this be causing an unintended short?

-

Keep digging, not sure what the answer is, but it is something unique to your particular circumstances.

I have 5 DNA200s, all in regular use, all using NI200, and all work fine without a single issue yet that wasnt of my own doing. -

Russ ModCrate said:

Just an update Mod Crate is going to do a run of the beta reference enclosure. We want to make a few functional alterations but I would like some community feedback.

1. Currently the case is designed to use the Evolv 510. Is that something everyone prefers or would you like the countersink removed and have a hole drilled so you may use FDV and other 510 connectors.

2. We also want to have multiple options for the rear half of the case so that users can choose larger capacity lipo batteries.

These are all the changes we have planned does anyone have any suggestions?

1) I would drill a hole to accommodate any commonly used 510. Drill/tap it to the smallest common hole and let the user enlarge it if they so choose. I am VERY partial to the Evolv 510 myself, but not everybody has access to them, or even cares for them.

2) The changeable back half is great, however I also suggest an additional 5mm in height, or at least an additional 2.5mm below the board. This allows for a XT30 or similar connector to fit under the JST connector.

For example, in this enclosure I added 2.5mm both above and below the board. See how pretty the XT30 sits in there. Sure beats directly soldering the bat to the board.

Something else I did was lower the window 2-3mm (though not shown in above photo). This reduces the danger area where people are pinching the ribbon cable under the Fire Button tang, versus when the window is centered between the fire button and the +/- buttons.

A paper template showing people where to tape the screen to the board, to match your window placement, would also be helpful. I had a friend mill me a jig to do my boards, but for a one-off DIYer correct screen placement with double back tape is a bit of a challenge.

Early Firmware and EScribe Suite Discussion Thread

in EScribe, Software and Firmware

Posted

The last few "Release Notes" are in Post #1 of this thread.

https://forum.evolvapor.com/topic/66731-topic/?do=findComment&comment=900118

Temp Dominant changes the control action (Display and the +/- buttons) to adjust temp by default instead of watts. I find it rather handy as I always leave my Mods on 200w and then let temp control it. So in day to day use, I just adjust temp.

Note: turn it off if you are running Kanthal, it is only of value if you are running temp sensing wire.